Search Results

- IDNO:

- 003377

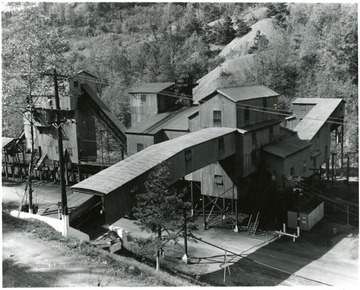

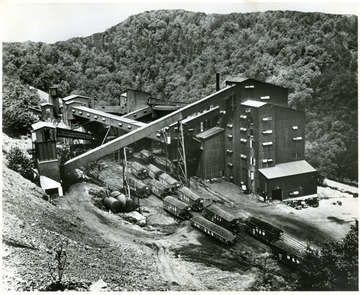

- Title:

- Mine No. 155 Tipple, Consolidation Coal Company, Van Lear, Kentucky

- Date:

- 1947/10/20

- IDNO:

- 003378

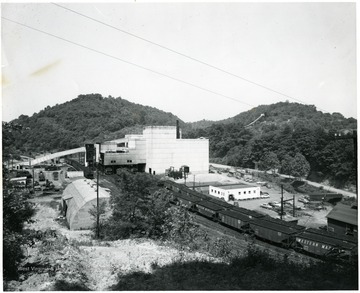

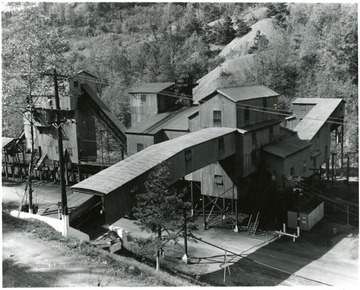

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Filled coal cars are lined up outside of the Williams Preparation Plant.

- IDNO:

- 003380

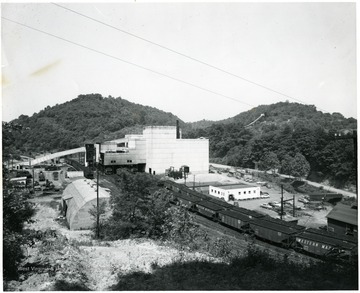

- Title:

- Georgetown Preparation Plant

- Description:

- Division of the Pittsburgh Consolidation Coal Co.

- IDNO:

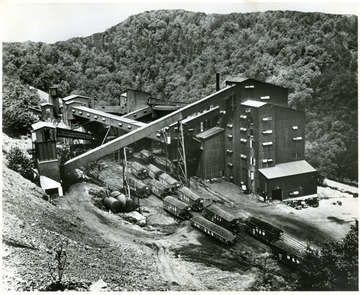

- 003381

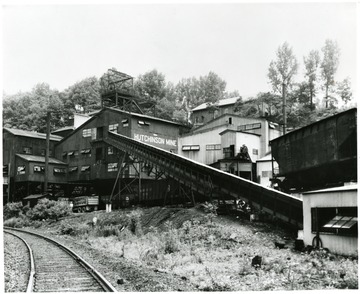

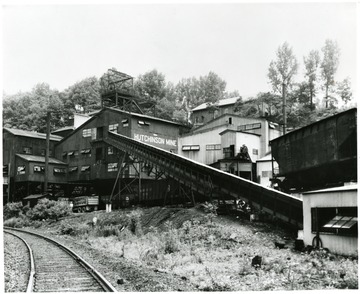

- Title:

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/12

- Description:

- Mine cars and buildings around the preparation plant.

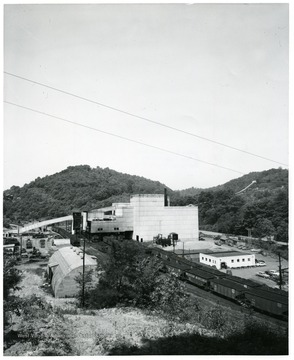

- IDNO:

- 003383

- Title:

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/10

- Description:

- Mine cars and buildings around the preparation plant.

- IDNO:

- 003385

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Large preparation plant with filled coal cars lining the outside.

- IDNO:

- 003388

- Title:

- Sheltered Conveyor

- Description:

- 'A sheltered conveyor brings the Disco product from the carbonizers to this sheltered mechanical cooling wharf. A method of careful cooling in motion prevents spontaneous firing of the fuel and avoids injury to the structure of the product. The wharf is contructed of a series of grates, which are successively raised and lowered in a wavelike manner to keep the Disco product in motion and convey it slowly, while it is being cooled, down to the discharge end of the wharf.

- IDNO:

- 003389

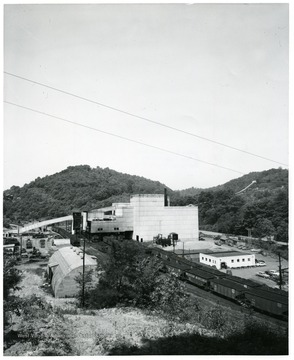

- Title:

- Harmar Preparation Plant

- Date:

- 1955/05/03

- Description:

- Scenic view of the Harmar mine facilities.

- IDNO:

- 003390

- Title:

- Amonate Preparation Plant, Pocahontas Fuel Company

- Description:

- Large plant with filled coal cars outside.

- IDNO:

- 003391

- Title:

- Consolidation Coal Company Mine No. 32, Fairmont, W. Va.

- Description:

- Train engine and filled coal cars outside of the preparation plant at Mine No. 32, Fairmont, W. Va.

- IDNO:

- 003392

- Title:

- Georgetown Preparation Plant

- Description:

- 'The Georgetown Prepatation Plant is here viewed from the north, showing the main entrance. Landscaping has begun and the company will build a sizable parking lot in front of the plant with auxiliary lots near the scale house (off the picture to the left) and at the track level in the rear. The enclosed raw coal conveyor and the refuse loading bin are shown at the right. This plant will serve as a central preparation facility for the strip mining and some of the underground mining operations of the Hanna Coal Company, Ohio operating division of Pittsburgh Coal Company. With a capacity of 1,500 tons of raw coal input per hour, Georgetown is the largest coal cleaning plant in the commerical bituminous industry. It has three cleaning circuits and five types of facilities for drying the coal. Integrated with the plant operation are special systems for cleaning and recirculating the water, thereby avoiding stream pollution, and for elimination of air pollution.'

- IDNO:

- 003393

- Title:

- Georgetown Preparation Plant

- Description:

- Georgetown Preparation Plant's raw coal conveyor and the refuse loading bin are shown in this picture.