Search Results

- IDNO:

- 003325

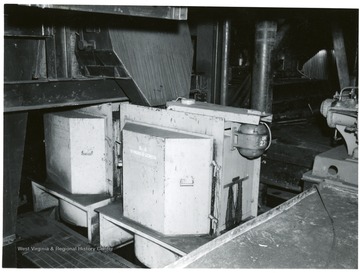

- Title:

- High Intensity Screens

- IDNO:

- 003326

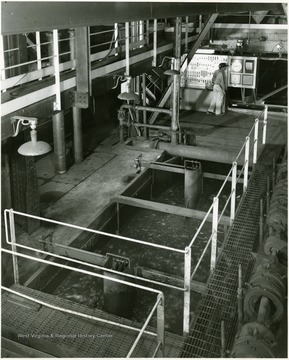

- Title:

- Head of Raw Coal Belt Conveyor with Magnetic Separator

- IDNO:

- 003330

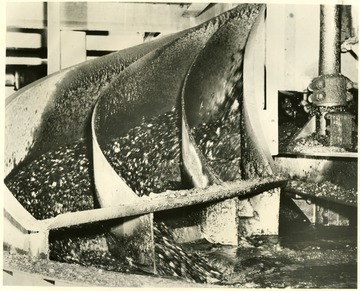

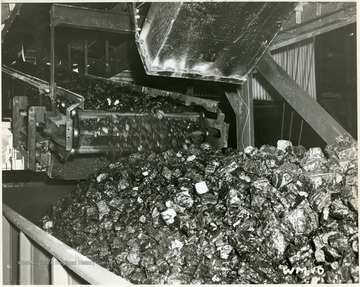

- Title:

- Chance Cone Feeding Coal

- Description:

- 'The sheltered construction of the processing equipment makes it difficult to photograph the coal in flow through the circuits, but this is a flash of the raw coal feed pouring into the 16.5 foot Chance cone. In this cone-shaped vessel, a mixture of sand and water is kept at a controlled gravity by agitation and by control of the proportions. This gravity is set to separate the clean coal from the refuse. The lighter coal is floated on top of the mix and guided to a discharge to continue its processing, which includes desanding, scrubbing, sizing, and moisture removal. The heavier refuse meanwhile sinks to the bottom and is passed to the refuse disposal system. This large cone has a capacity of 500 tons per hour.'

- IDNO:

- 003331

- Title:

- Loading Ramp to Cement Floor

- IDNO:

- 003332

- Title:

- Jeffrey Baum Jig at Jamison No. 9

- Date:

- 1954/10/05

- Description:

- Used to improve coal quality by reducing the ash.

- IDNO:

- 003333

- Title:

- Flat Bed with Water, Pittsburgh Consolidation Coal Company

- IDNO:

- 003334

- Title:

- Washing Coal with the Chance Cone System, Williams Preparation Plant, Pittsburgh Consolidation Coal Company

- IDNO:

- 003337

- Title:

- Loading Minus 5 Inch Coal at Williams Preparation Plant

- IDNO:

- 003338

- Title:

- Welder at Work Above a Loading Boom in a Preparation Plant

- IDNO:

- 003339

- Title:

- Coal Conveyors in Action at Arkwright

- IDNO:

- 003340

- Title:

- Coal Being Processed at Champion Cleaning Plant

- Date:

- 1929/02/18

- IDNO:

- 003341

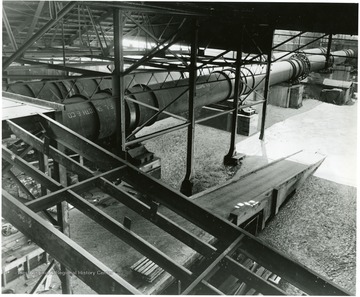

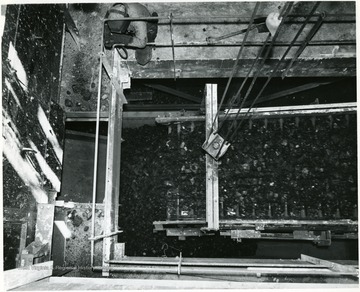

- Title:

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'