Search Results

- IDNO:

- 003337

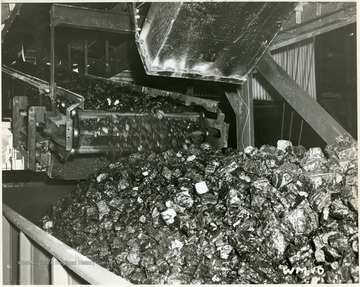

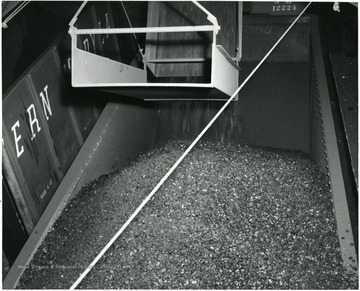

- Title:

- Loading Minus 5 Inch Coal at Williams Preparation Plant

- IDNO:

- 003338

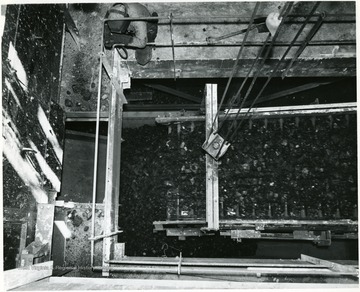

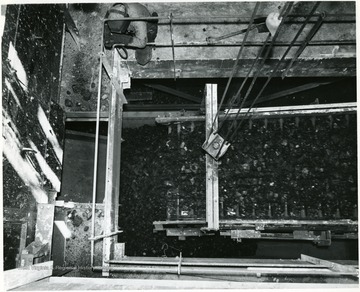

- Title:

- Welder at Work Above a Loading Boom in a Preparation Plant

- IDNO:

- 003339

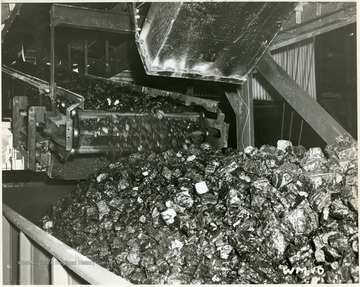

- Title:

- Coal Conveyors in Action at Arkwright

- IDNO:

- 003340

- Title:

- Coal Being Processed at Champion Cleaning Plant

- Date:

- 1929/02/18

- IDNO:

- 003341

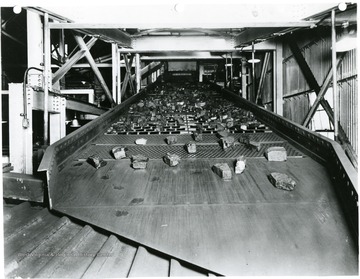

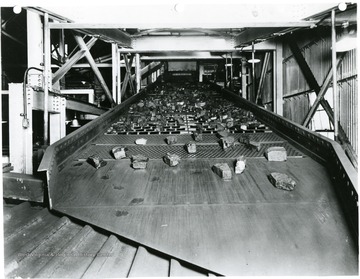

- Title:

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'

- IDNO:

- 003343

- Title:

- Main Shaker Screen and Step Plate

- Description:

- Coal moves across the main shaker screen.

- IDNO:

- 003344

- Title:

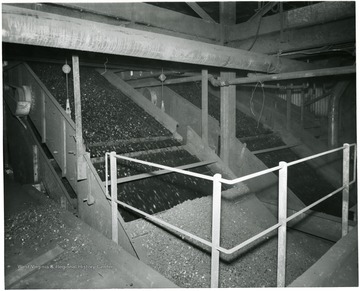

- Double Deck Vibrating Screens, Making Two Sizes of Stoker Coal

- IDNO:

- 003345

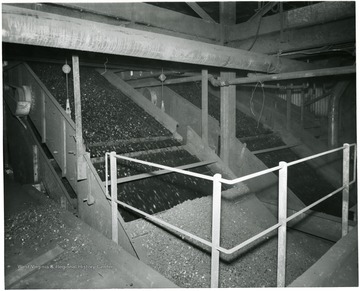

- Title:

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003346

- Title:

- Stoker Coal at Williams Preparation Plant

- Description:

- Coal traveling down a conveyor for processing.

- IDNO:

- 003347

- Title:

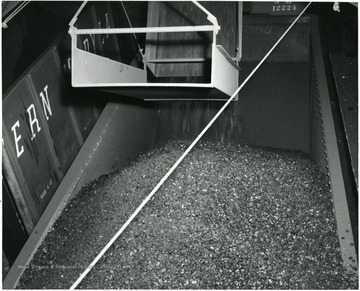

- Coal Loading in Process

- Description:

- Coal filling a bin.

- IDNO:

- 003350

- Title:

- Loading Booms in Action

- Date:

- undated

- Description:

- 'Shown here are the loading booms in action. Each of the five loading tracks is served by a loading boom, and the loading system is interconnected so as to permit blending of sizes and loading of any size group on any track. The loading booms gently lower the coal into the cars with a minimum of opportunity for dust or degradation. The loading facilities are sufficient to permit the loading of a car every two minutes. The adjoining track system permits rapid assembly of trains, interchange between the two railraods, and sufficient trackage for the storage of 858 railroad cars of 70 ton capacity.'

- IDNO:

- 003351

- Title:

- Conveyor Belt at Jamison No. 9

- Description:

- Coal traveling on a conveyor.