Search Results

- IDNO:

- 003420

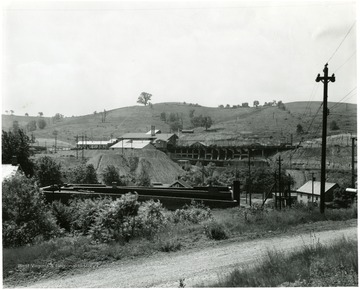

- Title:

- Disco Fuel

- Date:

- 1949/03/07

- Description:

- Disco fuel brought by conveyor to screen house and loading boom (shown), where blended and sized for market. At right, ascending conveyor.

- IDNO:

- 003421

- Title:

- Georgetown Preparation Plant

- Description:

- View of the preparation plant from the North East.

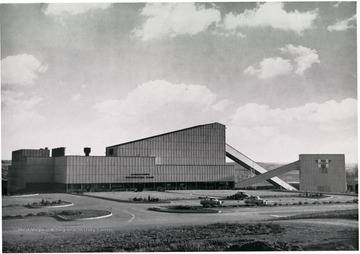

- IDNO:

- 003422

- Title:

- Georgetown Preparation Plant

- Description:

- Looking down from top of a raw coal conveyor at receiving station.

- IDNO:

- 003423

- Title:

- Georgetown Preparation Plant

- Description:

- 'The Georgetown Preparation Plant was the worlds largest commercial coal preparation plant, having a capacity of 1,500 tons per hour of raw coal, or 1,275 tons per hour of clean coal. The plant has facilities for dumping bottom-dump tractor-trailer and end-dump trucks, and for rotary and bottom dumping of railroad cars. Coal from these dumps goes into a 1,500 ton bin, from which it is conveyed on a 641 foot belt conveyor to the primary shaker screens. Whereas the conventional coal perparation plant provides only one circuit for all coal washed, the Georgetown plant is unique, in that it provides three separate washing circuites, each of which is designed to most efficiently clean a certain size fraction.'

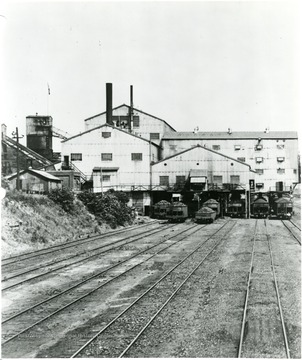

- IDNO:

- 003424

- Title:

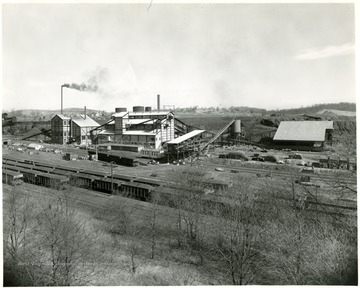

- Champion No. 1 Preparation Plant

- Description:

- This plant supplied coal for the Disco Plant.

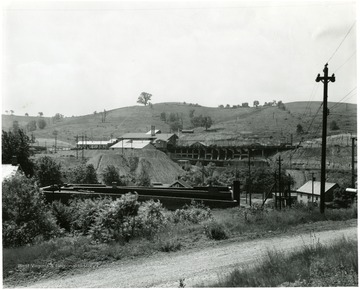

- IDNO:

- 003425

- Title:

- Disco Plant with Champion No. 1 Preparation Plant in Background

- IDNO:

- 003427

- Title:

- Hanna Coal Company Preparation Plant

- Description:

- 'Part of Hanna Coal Co. Prep. Plant. Shown is P.F., Tipple, Wash 7 X 0 inches, and Crusher.'

- IDNO:

- 003428

- Title:

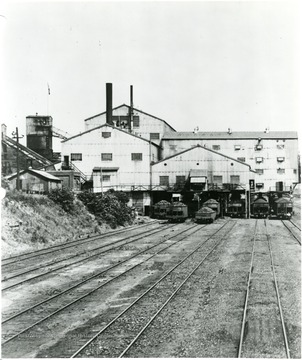

- Mathies Mine Preparation Plant

- Description:

- Coal preparation plant buildings at the Mathies Mine.

- IDNO:

- 003429

- Title:

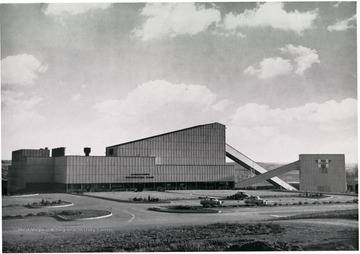

- Georgetown Preparation Plant

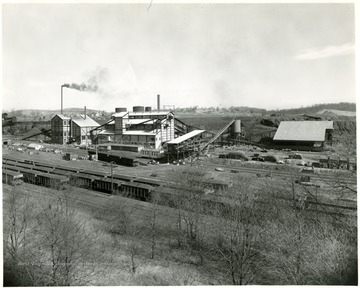

- Description:

- Front view of the Hanna Coal Co. Georgetown Prep. Plant

- IDNO:

- 003430

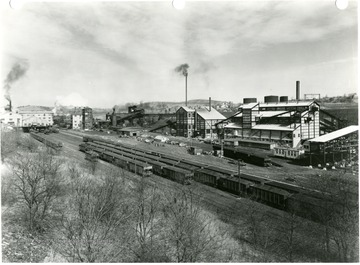

- Title:

- Georgetown Preparation Plant

- Description:

- View of the plant from across river.

- IDNO:

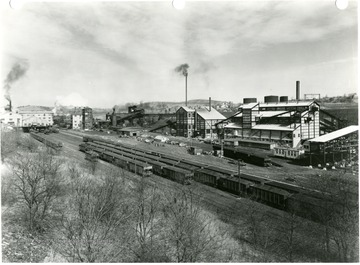

- 003431

- Title:

- Georgetown Preparation Plant

- Description:

- View of the plant from across river.

- IDNO:

- 003432

- Title:

- Georgetown Preparation Plant

- Date:

- 1953/10/15

- Description:

- View of the plant from across river.