Search Constraints

You searched for:

Acquisition Source

Craigo, Robert

Remove constraint Acquisition Source: Craigo, Robert

Topical Subjects

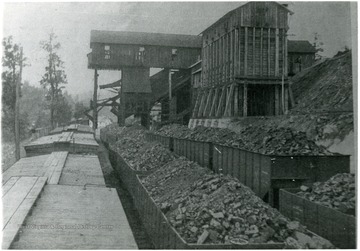

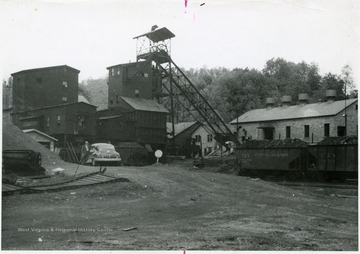

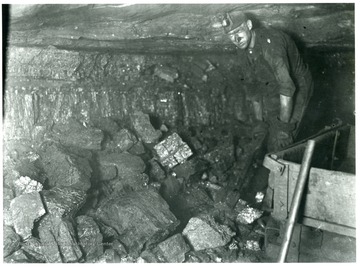

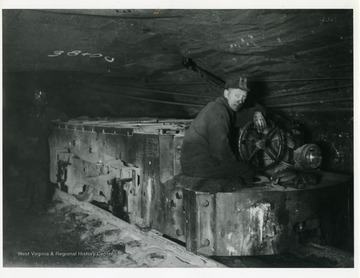

Coal mines and mining.

Remove constraint Topical Subjects: Coal mines and mining.

« Previous |

1 - 24 of 29

|

Next »