Search Results

- IDNO:

- 003332

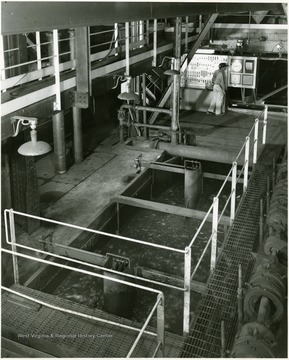

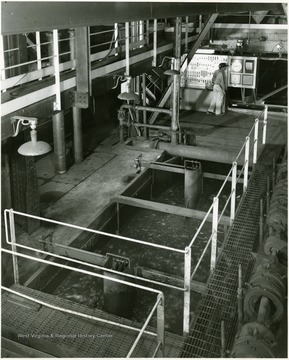

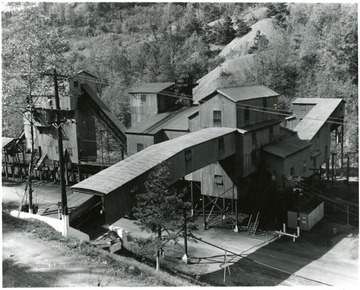

- Title:

- Jeffrey Baum Jig at Jamison No. 9

- Date:

- 1954/10/05

- Description:

- Used to improve coal quality by reducing the ash.

- IDNO:

- 003333

- Title:

- Flat Bed with Water, Pittsburgh Consolidation Coal Company

- IDNO:

- 003344

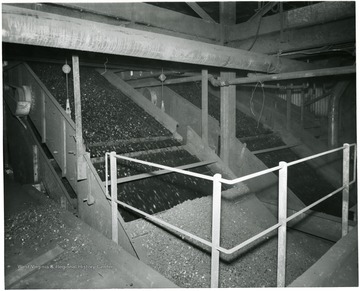

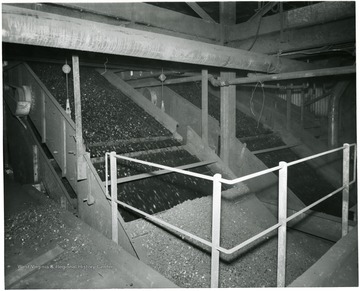

- Title:

- Double Deck Vibrating Screens, Making Two Sizes of Stoker Coal

- IDNO:

- 003345

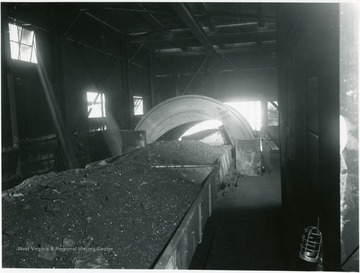

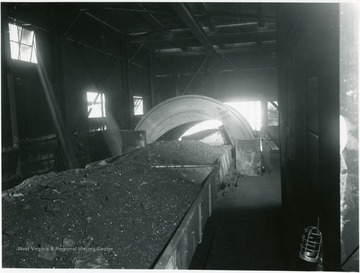

- Title:

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003348

- Title:

- Lump Coal Being Loaded onto Railroad Cars

- Description:

- 'All sizes of 'White Oak' prepared coal are loaded into railroad cars with loading booms to minimize breakage and preserve the best appearance of the coal. It would be useless to carefully mine and screen our coal if we did not use proper care in loading it into the railroad cars. These booms lower to the bottom of the car when it is first placed under the tipple for loading, and raised from time to time as the car fills up. Note how perfectly screened this lump coal appears on the boom! Not a sign of slack to be seen. Treated for dust if desired.'

- IDNO:

- 003355

- Title:

- Link-Belt Rotary Mine Car Dumper, Pocahontas Fuel Company, Itmann, W. Va.

- Date:

- 1951/11

- Description:

- 'Link-Belt 33460, Link-Belt rotary mine car dumper at Heavy-Media coal preparation plant of Pocahontas Fuel Co. Inc., Itmann, W. Va. Capacity of plant is 750 tons of raw coal per hour. Nov. 1951'

- IDNO:

- 003356

- Title:

- Eccles No. 5 Machine Shop

- Description:

- 'Sherman A. Clay in center in front of door. He is donor's grandfather.'

- IDNO:

- 003364

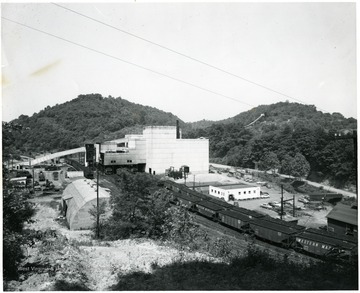

- Title:

- Consolidation Coal Company Mine No. 32, Fairmont, W. Va.

- Description:

- Scenic view of Mine No. 32 at Fairmont, W. Va.

- IDNO:

- 003366

- Title:

- Raw Coal Conveyor System

- Description:

- Conveyor belt in the middle of the mountains.

- IDNO:

- 003377

- Title:

- Mine No. 155 Tipple, Consolidation Coal Company, Van Lear, Kentucky

- Date:

- 1947/10/20

- IDNO:

- 003378

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Filled coal cars are lined up outside of the Williams Preparation Plant.

- IDNO:

- 003380

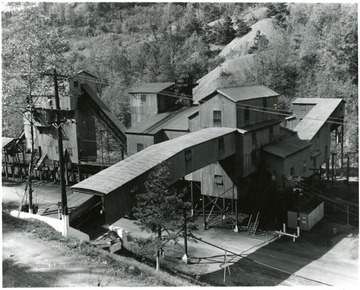

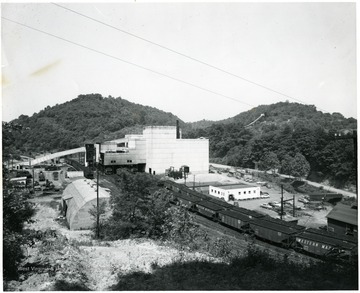

- Title:

- Georgetown Preparation Plant

- Description:

- Division of the Pittsburgh Consolidation Coal Co.