Search Results

- IDNO:

- 002638

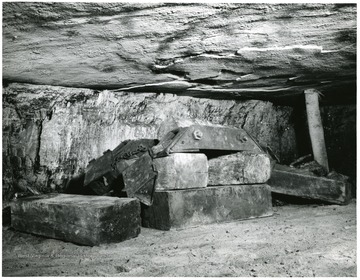

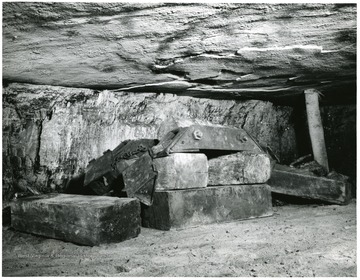

- Title:

- Wood Crib with Both Releases Tripped and Crib Collapsed at Pocahontas No. 4 Coal Bed, Helen, W. Va.

- Description:

- 'Modified Longwall Mining with a German Coal Planer. Progress Report 2: Completion of Mining in three Adjacent Panels in the Pocahontas No. 4 Coal Bed, Helen, W. Va.' If this photograph is used for publication, please give credit to the Bureau of Mines, United States, Department of Interior.

- IDNO:

- 002639

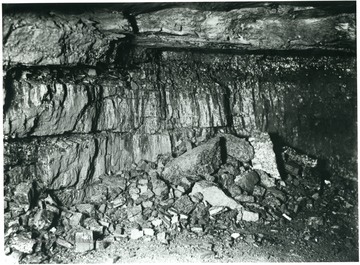

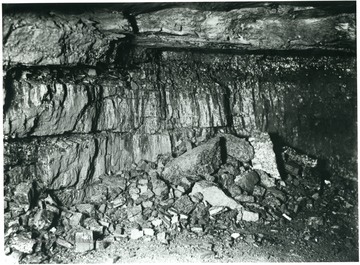

- Title:

- Sewall Coal Seam Worked by the New River Coal Company

- Description:

- 'All white oak mines work the same seam of coal, viz: Sewall. THe face of one of the working places or rooms is shown in this picture. The coal averages about 48 to 50 inches in thickness. This working place is now ready to be cut by the undercutting machine, so it can be shot down be the miner and loaded into cars for transportation to the tipple. The white line on the roof in this picture is the center line of the room set by the engineers to guide the men operating the mining machine in driving the room straight.'

- IDNO:

- 002641

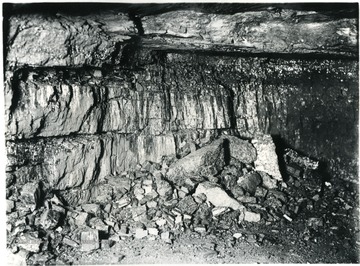

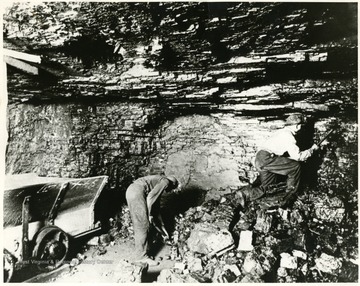

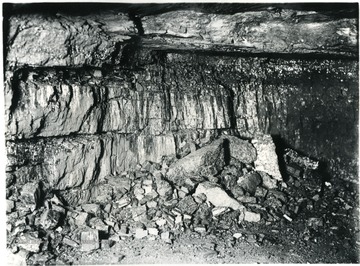

- Title:

- Coal Nearly Ready to be Shot Down

- Description:

- Notice the preparatory cut and the 3 charge-holes near floor of the mine.

- IDNO:

- 002642

- Title:

- Breaker Shot

- Description:

- 'Probably no phase of coal preparation requires the supervision and care that must be given to shooting practices. The type of explosive used is a safety powder known as "Duobel" and has been selected because it is most suitable for the coal mined in the White Oak Mines. Not only must the explosive be of the best quality and best suited for the work of breaking down the coal, but its use must be supervised and restricted. The proper amount to use; the size of the cartridge; the manner of tamping and many other details are looked after so that a maximum of lump and coarse coal is produced after shooting. This view shows the working place after the 'breaker shot' has been fired.'

- IDNO:

- 002643

- Title:

- Breaker Shot

- Description:

- 'Probably no phase of coal preparation requires the supervision and care that must be given to shooting practices. The type of explosive used is a safety powder known as "Duobel" and has been selected because it is most suitable for the coal mined in the White Oak Mines. Not only must the explosive be of the best quality and best suited for the work of breaking down the coal, but its use must be supervised and restricted. The proper amount to use; the size of the cartridge; the manner of tamping and many other details are looked after so that a maximum of lump and coarse coal is produced after shooting. This view shows the working place after the 'breaker shot' has been fired.'

- IDNO:

- 002644

- Title:

- Area worked by Coal Cutters

- Description:

- Print possibly overexposed.

- IDNO:

- 002647

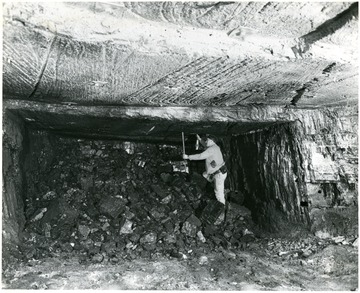

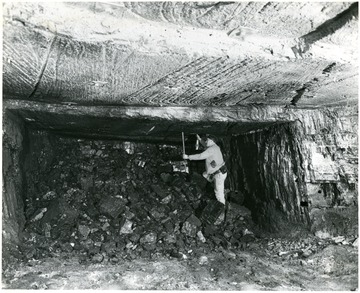

- Title:

- Shot Down Coal at Jamison Coal Mine No. 9

- Description:

- Miner works on pile of shot down coal.

- IDNO:

- 002648

- Title:

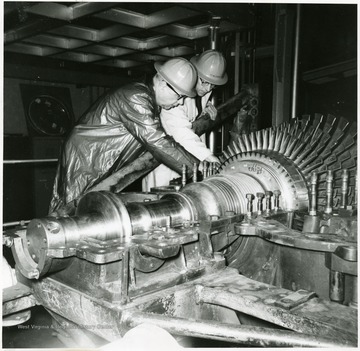

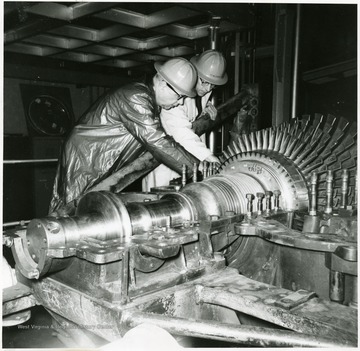

- Proper Positioning of the Turbine Rotor in Its Casing

- Date:

- 1960-1970

- Description:

- J.P. McGee, Acting Research Director, and Jack Smith, in Charge of the Gas Turbine Development Project discuss proper positioning of the turbine rotor in its casing.

- IDNO:

- 002653

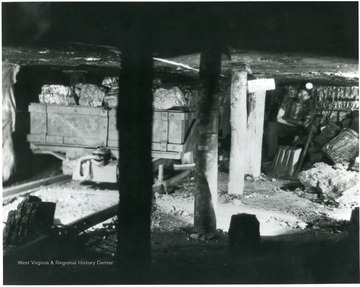

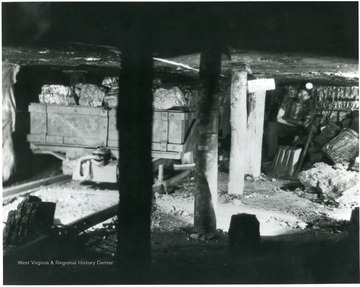

- Title:

- Loaded Mine Car

- Description:

- 'This miner has just completed loading a mine car of weighing net about two and one-half tons, and is waiting for a locomotive to come along and take it out and give him another empty car. An industrious miner will load about six and sometimes eight of these cars in one day. This is a wooden mine car that is now being rapidly replaced by steel mine car equipment. The number of post shown in this picture indicate again the immense amount of timber required to conduct operations in a safe manner.'

- IDNO:

- 002654

- Title:

- Miner Testing for Gas at Consol. No. 32 Mine

- Date:

- 1957

- IDNO:

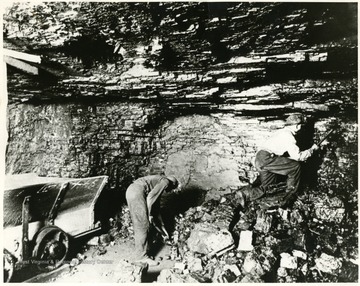

- 002656

- Title:

- Miners at Work

- Description:

- 'Note the wooden mine car. It is of the Barnestown shaft which was the first shaft, of 100 feet in depth, in the valley.'

- IDNO:

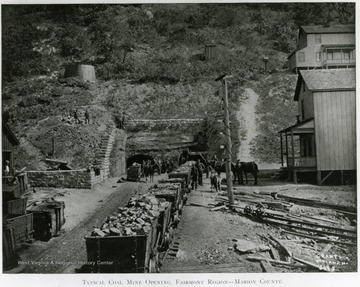

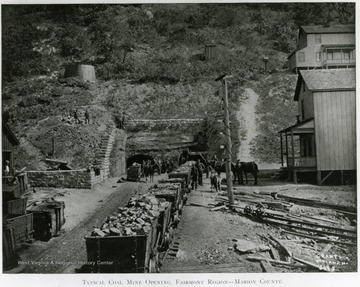

- 002659

- Title:

- Typical Coal Mine Entrance, Fairmont Region, Marion County, W. Va.

- Date:

- ca. 1901

- Description:

- Coal mine opening around the Fairmont region in Marion county. Line of filled coal cars with men and horses standing next to them.