Search Results

- IDNO:

- 002681

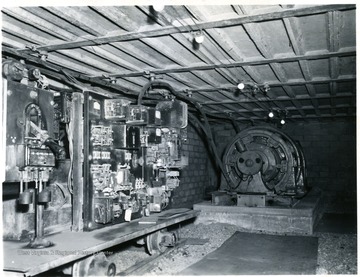

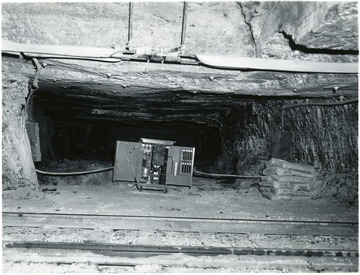

- Title:

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002682

- Title:

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002683

- Title:

- Coal Shuttle in Jamison Mine No. 9

- IDNO:

- 002684

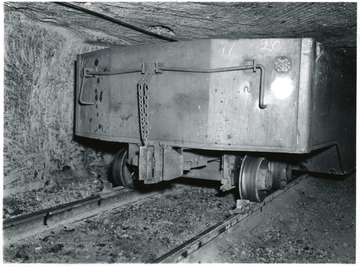

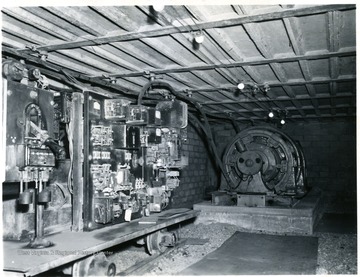

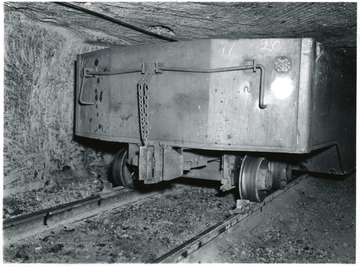

- Title:

- Mine Car

- Description:

- Mine car traveling through the mine.

- IDNO:

- 002685

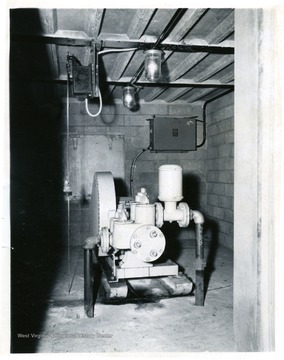

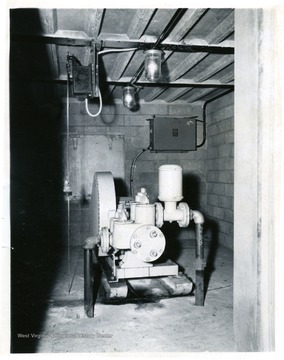

- Title:

- Diaphram Pump at Jamison Mine No. 9

- IDNO:

- 002686

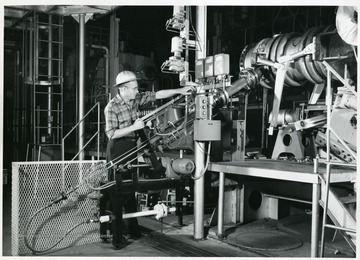

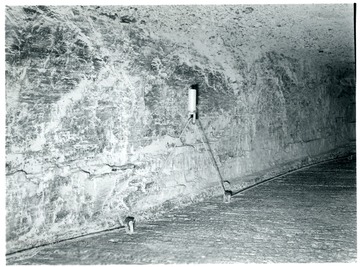

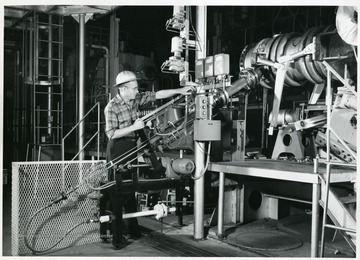

- Title:

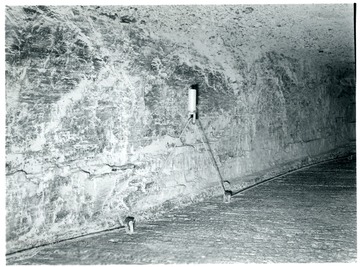

- Sampling Hot Ash-Laden Gas

- Date:

- ca. 1960-1970

- Description:

- 'A small portion of the hot ash-laden gas stream entering the turbine is continuously removed by this ash-sampling unit. Data from the operation of this unit is analyzed to determine the concentration, size, and composition of the ash in the hot gases entering the turbine.'

- IDNO:

- 002687

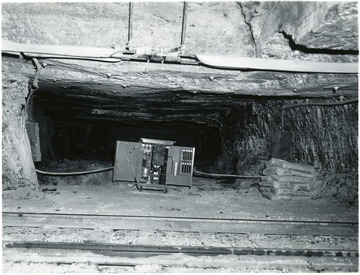

- Title:

- ITE Circuit Breaker at Jamison Mine No. 9

- IDNO:

- 002688

- Title:

- Rock Dusted Mine Shaft at Jamison No. 9

- Description:

- Jamison No. 9 Mine shaft with a tensioning device on a cable.

- IDNO:

- 002690

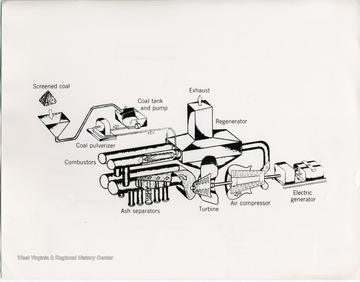

- Title:

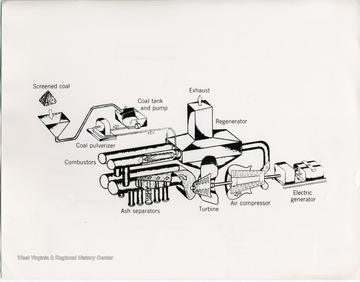

- Schematic Diagram of Coal-Fired Gas Turbine

- Date:

- ca. 1960-1970

- Description:

- Coal crushed to 3/16-inch by 0 is pumped to a pulverizer that grinds it to 90-per cent hrough 200-mesh. The product is mixed with air and burned in the combustors. Hot high-speed gas from the ash separators drives the turbine, air compressor, and electric generators. Exhaust from the turbine passes through a regenerator that preheats compressed air to the combustors. If used, please credit Bureau of Mines, U.S. Department of the Interior.

- IDNO:

- 002691

- Title:

- Miner Bathing in a Small Tub

- Description:

- Miner washing himself in a small washtub.

- IDNO:

- 002692

- Title:

- New Rotor Blade Design

- Date:

- 1960-1970

- Description:

- This mock-up shows the new blade design being tested by the Bureau of Mines. The base of the blade is thicker and there is a strip of titanium carbide at the point of previous severe erosion. If used, please credit Bureau of Mines, U.S. Department of the Interior.During LDC's final 1,100-hour run, this rotor blade (arrow) was undercut by ash flowing along the rotor past the tips of the stator blades. If used, please credit Bureau of Mines, U.S. Department of the Interior.

- IDNO:

- 002693

- Title:

- New Rotor Blade Design

- Date:

- 1960-1970

- Description:

- This mock-up shows the new blade design being tested by the Bureau of Mines. The base of the blade is thicker and there is a strip of titanium carbide at the point of previous severe erosion. If used, please credit Bureau of Mines, U.S. Department of the Interior.During LDC's final 1,100-hour run, this rotor blade (arrow) was undercut by ash flowing along the rotor past the tips of the stator blades. If used, please credit Bureau of Mines, U.S. Department of the Interior.