Search Results

- IDNO:

- 003384

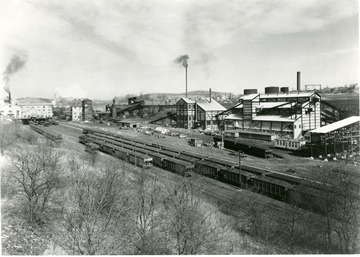

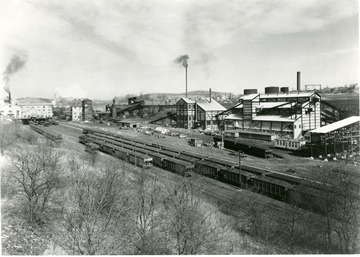

- Title:

- Disco Plant with Champion No. 1 Preparation Plant in Background

- Description:

- Line of large coal buildings. Filled coal cars lined up outside as well.

- IDNO:

- 003385

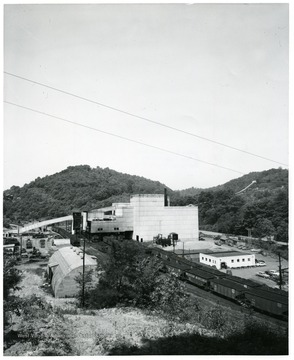

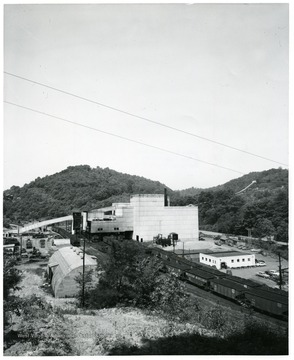

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Large preparation plant with filled coal cars lining the outside.

- IDNO:

- 003386

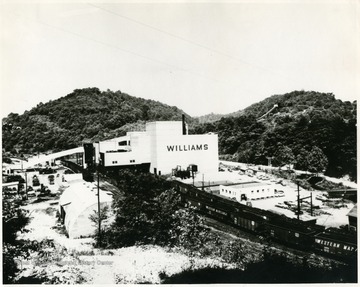

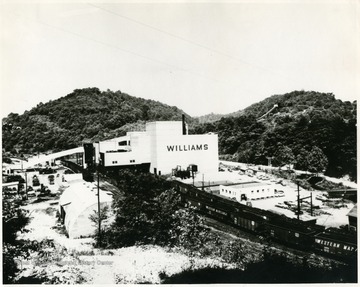

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Date:

- ca. 1953

- Description:

- 'An overall view of the new plant at Williams No. 98 Mine of Consolidation Coal Compnay (W. Va.) is shown. Coal comes from the mine on a 558 foot conveyor belt at the left to the top of the plant past the old tipple (shown dark against the new structure) which is now being removed. Through intricate processes it is screened and sized and loaded into railroad cars on four tracks which pass under the tipple (center). Impurities removed from the coal are carried on another long conveyor to a hilltop slate dump shown in the extreme upper right corner. This mine is named for Eugene Williams of Romney, W. Va. Mr. Williams is Chairman of the Board of Western Maryland Railroad. Williams Preparation Plant, convering over three acres of floor space on eight levels is a steel and concrete structure 100 feet high and fully enclosed without a single window. this windowless 'factory' is a mystifying innovation to all who visit the plant. It is equipped with a ventilating system, fluorescent lighting, and a complete vacuum type dust collection system that gather in all air borne particles at their source. All of these measures promote health, safety and good housekeeping. The raw coal is delivered to the preparation plant at a rate of 450 tons per hour by a 558 foot belt which picks up the coal at the rotary mine car dump at the bottom of the slope. After the coal is crushed down to 5 inch top size the raw coal is fed into a 15 foot diameter chance cone yielding 278 tons of 'float-kleen' coal per hour. The washing process operates on the principle of gravity separation, a fluid mass of sand and water being utilized as the density medium. Designed and built by Fairmont Machinery Company placed in operation March 31, 1953; No windows, dust collection system; track storage, 100 empties, 80 loads; Present daily capacity, 8500 tons; potential daily capacity, 15,000 tons; coal reserves, 80,000,000 tones, Pittsburgh seam; slack dried, centrifugal and thermal dryers; oil treating facilities for stoker grades; served by two railroads, WM and B&O; Plant named for Eugene Williams of Romney, W. Va. Board Chairman of the Western Maryland Railroad.'

- IDNO:

- 003387

- Title:

- Acme Mine

- Description:

- View of mine buildings at the Acme Mine.

- IDNO:

- 003388

- Title:

- Sheltered Conveyor

- Description:

- 'A sheltered conveyor brings the Disco product from the carbonizers to this sheltered mechanical cooling wharf. A method of careful cooling in motion prevents spontaneous firing of the fuel and avoids injury to the structure of the product. The wharf is contructed of a series of grates, which are successively raised and lowered in a wavelike manner to keep the Disco product in motion and convey it slowly, while it is being cooled, down to the discharge end of the wharf.

- IDNO:

- 003389

- Title:

- Harmar Preparation Plant

- Date:

- 1955/05/03

- Description:

- Scenic view of the Harmar mine facilities.

- IDNO:

- 003391

- Title:

- Consolidation Coal Company Mine No. 32, Fairmont, W. Va.

- Description:

- Train engine and filled coal cars outside of the preparation plant at Mine No. 32, Fairmont, W. Va.

- IDNO:

- 003392

- Title:

- Georgetown Preparation Plant

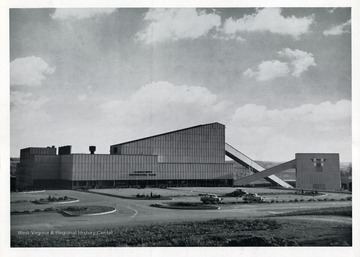

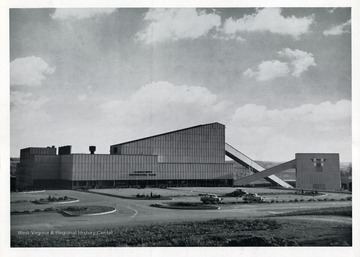

- Description:

- 'The Georgetown Prepatation Plant is here viewed from the north, showing the main entrance. Landscaping has begun and the company will build a sizable parking lot in front of the plant with auxiliary lots near the scale house (off the picture to the left) and at the track level in the rear. The enclosed raw coal conveyor and the refuse loading bin are shown at the right. This plant will serve as a central preparation facility for the strip mining and some of the underground mining operations of the Hanna Coal Company, Ohio operating division of Pittsburgh Coal Company. With a capacity of 1,500 tons of raw coal input per hour, Georgetown is the largest coal cleaning plant in the commerical bituminous industry. It has three cleaning circuits and five types of facilities for drying the coal. Integrated with the plant operation are special systems for cleaning and recirculating the water, thereby avoiding stream pollution, and for elimination of air pollution.'

- IDNO:

- 003393

- Title:

- Georgetown Preparation Plant

- Description:

- Georgetown Preparation Plant's raw coal conveyor and the refuse loading bin are shown in this picture.

- IDNO:

- 003394

- Title:

- Georgetown Preparation Plant

- Description:

- 'The Georgetown Preparation Plant is the world's largest commerical coal preparation plant, having a capacity of 1,500 tons per hour of raw coal, or 1,275 tons per hour of clean coal.'

- IDNO:

- 003395

- Title:

- Four States Mine, Marion County, W. Va.

- Description:

- Exterior buildings of the Four States Mine in Marion County, W. Va.

- IDNO:

- 003397

- Title:

- Jamison No. 9 Preparation Plant