Search Results

- IDNO:

- 002677

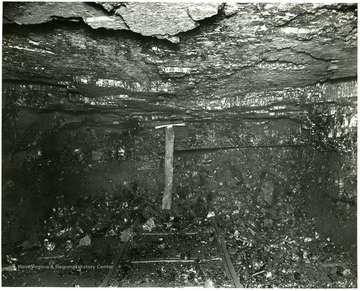

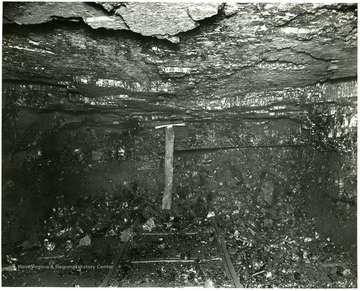

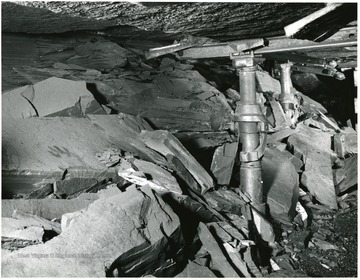

- Title:

- Elkhorn No. 3 Seam, Mine 206, Kentucky

- Description:

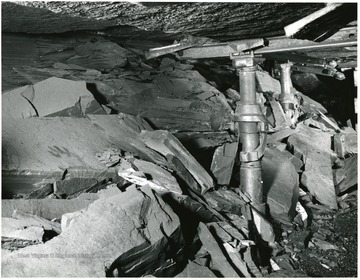

- Shows timber roof-support and mine railway track.

- IDNO:

- 002679

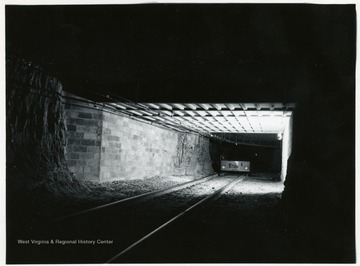

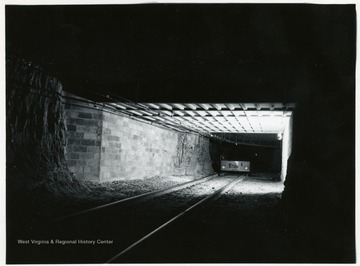

- Title:

- Overcast in Jamison No. 9 Mine Shaft Bottom

- Description:

- Overcast, where two air currents cross in a mine, at the Jamison Mine No. 9 shaft bottom.

- IDNO:

- 002682

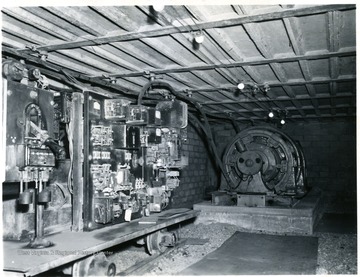

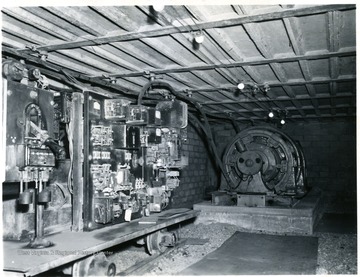

- Title:

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002692

- Title:

- New Rotor Blade Design

- Date:

- 1960-1970

- Description:

- This mock-up shows the new blade design being tested by the Bureau of Mines. The base of the blade is thicker and there is a strip of titanium carbide at the point of previous severe erosion. If used, please credit Bureau of Mines, U.S. Department of the Interior.During LDC's final 1,100-hour run, this rotor blade (arrow) was undercut by ash flowing along the rotor past the tips of the stator blades. If used, please credit Bureau of Mines, U.S. Department of the Interior.

- IDNO:

- 002701

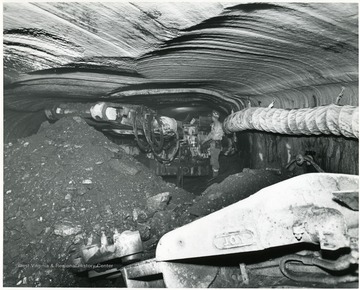

- Title:

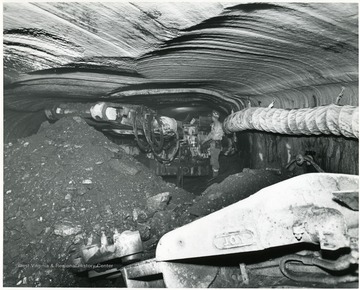

- Continuous Mining Machine (Middle) and Loading Machine (Bottom)

- Date:

- 1959/04/07

- Description:

- Mountaineer Coal Company, Division of Consolidation Coal Company.

- IDNO:

- 002703

- Title:

- Shuttle Car Approaches Mine Railway Track.

- IDNO:

- 002707

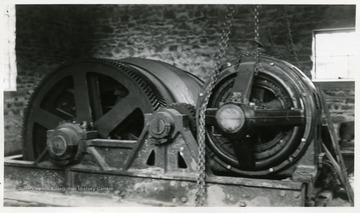

- Title:

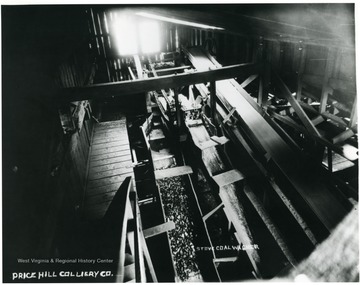

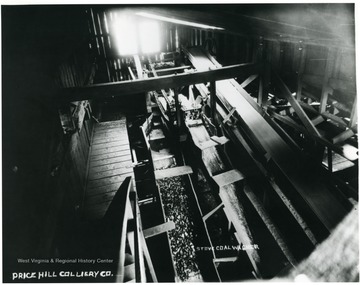

- Stove Coal Washer, Price Hill Colliery Company

- Description:

- View of the mechanics of a stove coal washer.

- IDNO:

- 002710

- Title:

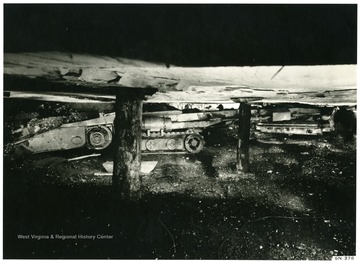

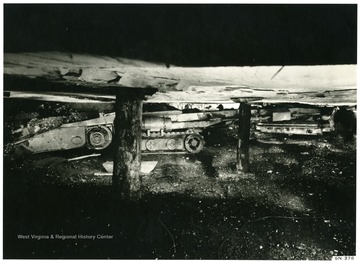

- Boilers in a Coal Mine

- Description:

- View of a row of boilers and equipment in an underground mine.

- IDNO:

- 002714

- Title:

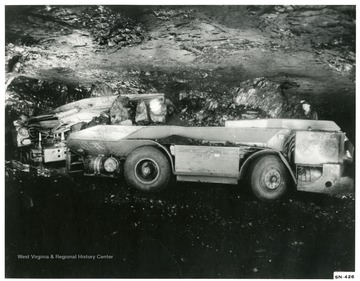

- Continuous Miner in a Tunnel Approximately 4 Feet High

- Description:

- Continuous mining machine at work.

- IDNO:

- 002719

- Title:

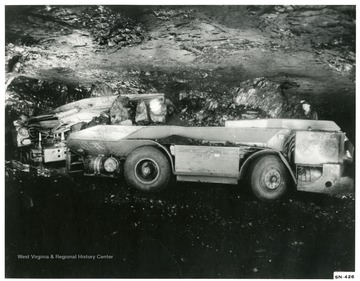

- Loaded Shuttle Car

- Description:

- Shuttle car in an underground mine, loaded with coal.

- IDNO:

- 002721

- Title:

- Interior of a Coal Mine with Roof Supports Along Longwall Face

- Description:

- 'Modified longwall mining with a German coal planer. Progress report 2: Completion of mining in three adjacent panels in the Pocahontas no. 4 coal bed, Helen, W. Va.' Please give credit to the Bureau of Mines, United States, Department of Interior.

- IDNO:

- 002734

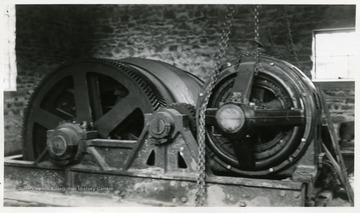

- Title:

- Electric Motor, Thomas, W. Va.

- Description:

- Close view of an electric motor at a coal mine site in Thomas, W. Va.