Search Results

- IDNO:

- 003337

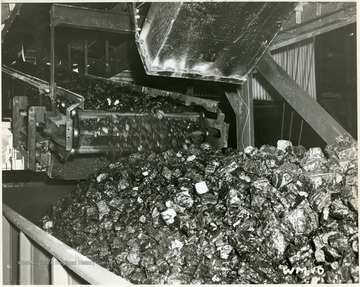

- Title:

- Loading Minus 5 Inch Coal at Williams Preparation Plant

- IDNO:

- 003338

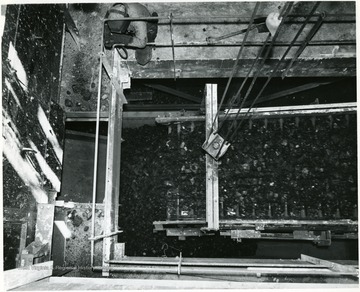

- Title:

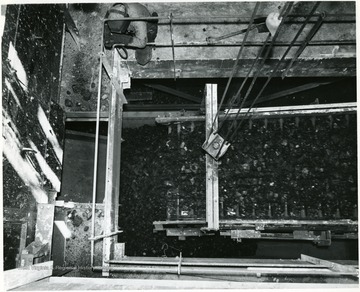

- Welder at Work Above a Loading Boom in a Preparation Plant

- IDNO:

- 003339

- Title:

- Coal Conveyors in Action at Arkwright

- IDNO:

- 003340

- Title:

- Coal Being Processed at Champion Cleaning Plant

- Date:

- 1929/02/18

- IDNO:

- 003341

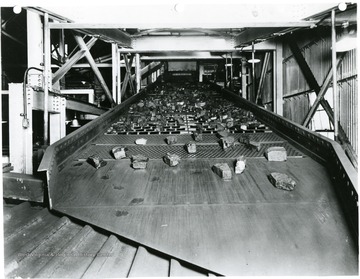

- Title:

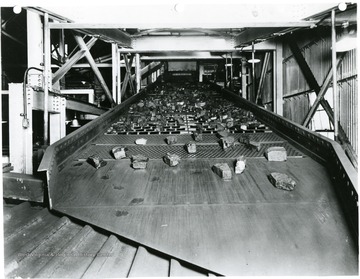

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'

- IDNO:

- 003342

- Title:

- Coal Cars at Lochgelly Mine

- Date:

- 1952/04/20

- IDNO:

- 003343

- Title:

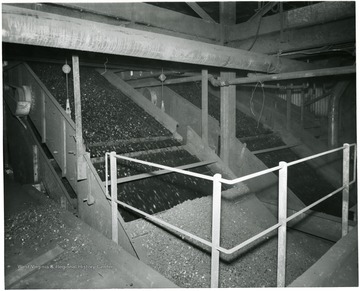

- Main Shaker Screen and Step Plate

- Description:

- Coal moves across the main shaker screen.

- IDNO:

- 003344

- Title:

- Double Deck Vibrating Screens, Making Two Sizes of Stoker Coal

- IDNO:

- 003345

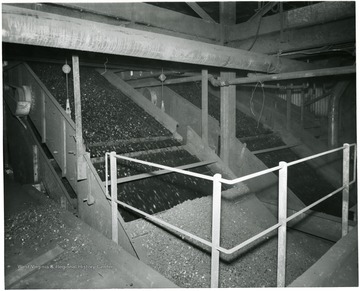

- Title:

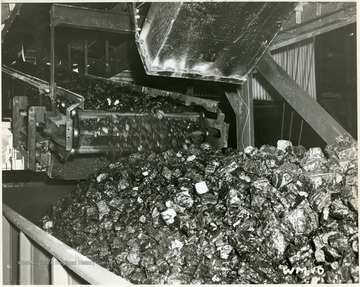

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003346

- Title:

- Stoker Coal at Williams Preparation Plant

- Description:

- Coal traveling down a conveyor for processing.

- IDNO:

- 003347

- Title:

- Coal Loading in Process

- Description:

- Coal filling a bin.

- IDNO:

- 003348

- Title:

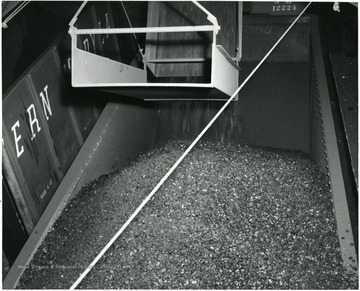

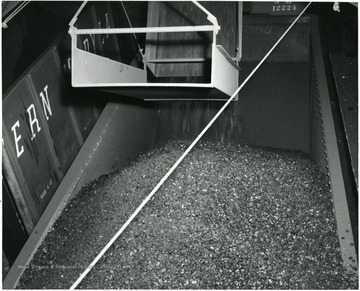

- Lump Coal Being Loaded onto Railroad Cars

- Description:

- 'All sizes of 'White Oak' prepared coal are loaded into railroad cars with loading booms to minimize breakage and preserve the best appearance of the coal. It would be useless to carefully mine and screen our coal if we did not use proper care in loading it into the railroad cars. These booms lower to the bottom of the car when it is first placed under the tipple for loading, and raised from time to time as the car fills up. Note how perfectly screened this lump coal appears on the boom! Not a sign of slack to be seen. Treated for dust if desired.'