Search Results

- IDNO:

- 003349

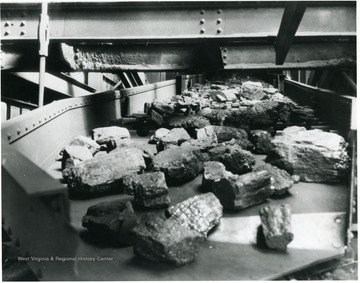

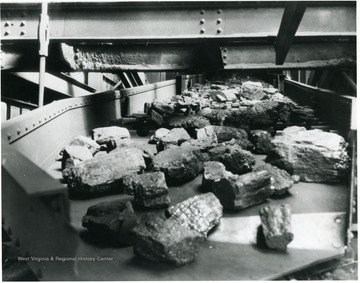

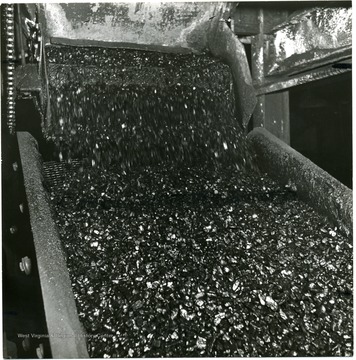

- Title:

- Screening and Sizing

- Description:

- 'The size and design of the shaker screens now in use at the White Oak mines are the best that an experience of twenty years in preparing Smokeless Coal has found to be the best and yield a satisfactory screened and sized coal. A screen must first be of ample size to take care of the amount of tonnage passing over it, because crowding and overloading a screen results in poorly screened and poorly sized coal. The screen shown in this picture is handling 400 tons per hour and still has ample screening space to spare. The flow of coal over these big 'White Oak' shaker screens is controlled by a feeder which cannot be tampered with; therefore, the screen cannot be overloaded. Note the 'lip' type of slotted screen plate used. It cannot become stopped up by coal sticking in the slots because the slots are wider at the base than at the top and are there fore self clearing. The 'lips' keep the coal turning over and over so it is impossible for slack to ride over on the larger pieces. The coal never falls; it is always sliding while being screened which helps prevent breakage. Note the uniform size and firm character of the lump coal which has passed over the egg screen shown in this picture.'

- IDNO:

- 003350

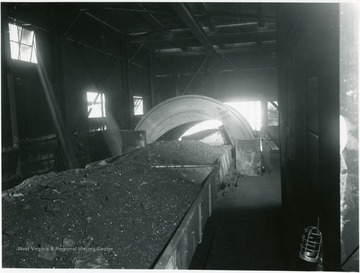

- Title:

- Loading Booms in Action

- Date:

- undated

- Description:

- 'Shown here are the loading booms in action. Each of the five loading tracks is served by a loading boom, and the loading system is interconnected so as to permit blending of sizes and loading of any size group on any track. The loading booms gently lower the coal into the cars with a minimum of opportunity for dust or degradation. The loading facilities are sufficient to permit the loading of a car every two minutes. The adjoining track system permits rapid assembly of trains, interchange between the two railraods, and sufficient trackage for the storage of 858 railroad cars of 70 ton capacity.'

- IDNO:

- 003351

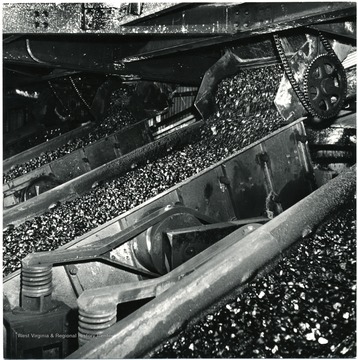

- Title:

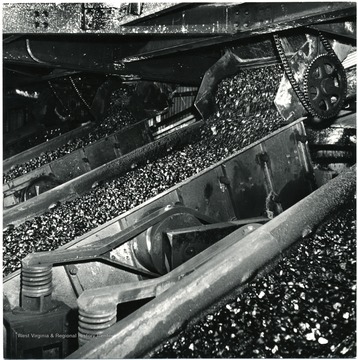

- Conveyor Belt at Jamison No. 9

- Description:

- Coal traveling on a conveyor.

- IDNO:

- 003352

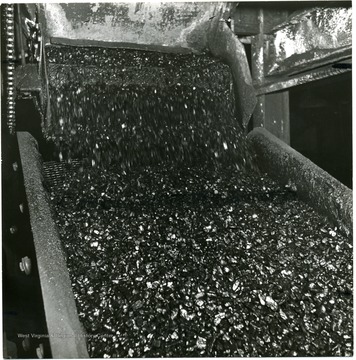

- Title:

- Coal Being Processed

- Date:

- 1947/07

- Description:

- Coal traveling on conveyors. Credit Must Be Given. Not to be reproduced without written license from William Vandivert.

- IDNO:

- 003353

- Title:

- Oil Treatment, Stoker Coal

- Date:

- 1947/07

- Description:

- Coal on a conveyor.

- IDNO:

- 003354

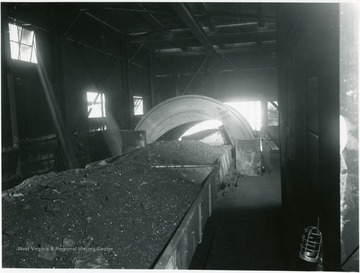

- Title:

- Interior of the Hutchinson Preparation Plant

- Description:

- Miner examines coal traveling down a conveyor inside the Hutchinson Preparation Plant, Pittsburgh Consolidation Coal Company.

- IDNO:

- 003355

- Title:

- Link-Belt Rotary Mine Car Dumper, Pocahontas Fuel Company, Itmann, W. Va.

- Date:

- 1951/11

- Description:

- 'Link-Belt 33460, Link-Belt rotary mine car dumper at Heavy-Media coal preparation plant of Pocahontas Fuel Co. Inc., Itmann, W. Va. Capacity of plant is 750 tons of raw coal per hour. Nov. 1951'

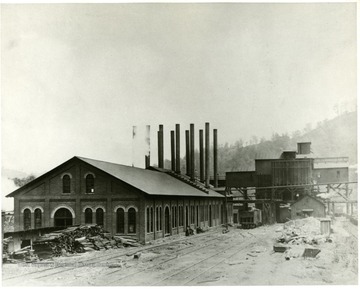

- IDNO:

- 003356

- Title:

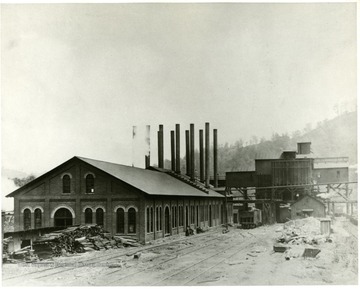

- Eccles No. 5 Machine Shop

- Description:

- 'Sherman A. Clay in center in front of door. He is donor's grandfather.'

- IDNO:

- 003357

- Title:

- Eccles No. 5 Miners

- Description:

- Probably was Fred Boyd Wiseman directly behind mine car (with cop. rt. arm lifted up).

- IDNO:

- 003358

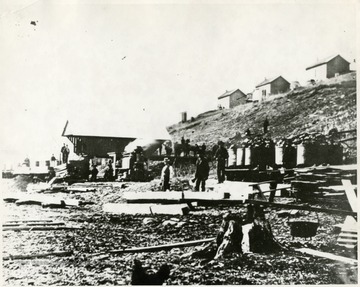

- Title:

- Monongah Mine No. 6, Marion County, W. Va.

- Description:

- A Fairmont Coal Company operation showing the tipple connected to a preparation building with smokestacks.

- IDNO:

- 003359

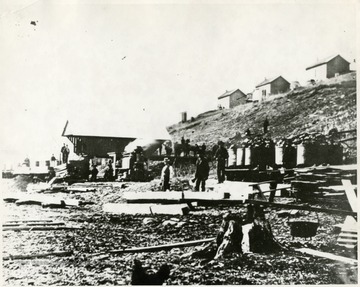

- Title:

- Miners at Gaston Mine Plant

- Date:

- undated

- Description:

- 'The Gaston Gas Coal Company, Gaston Mine Plant. Located one half mile South of Hunsaker Bridge on West Fork River. Owned by James Otis Watson and successor to American Coal Company's mining plant, built in 1852 at the Baltimore and Ohio Railroad Depot. This mine founded in 1875, closed in 1925. Picture shows 15 drop-bottom railroad cars called 'Hoppers.' These cars average 55 ton coal carrying capacity.'

- IDNO:

- 003360

- Title:

- New River Coal Company Mine and Miner's Houses

- Description:

- Tipple of a mine with houses for the miners located in the area behind the tipple.