Search Results

- IDNO:

- 003292

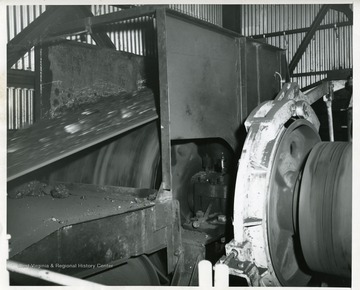

- Title:

- Head End Drive and Belt Conveyor with Braking Mechanism, Jamison No. 9 Mine

- Description:

- Head and drive belt conveyor with braking mechanism is ready to be used.

- IDNO:

- 003293

- Title:

- Visitors Pose with Hanna Coal Company's Mountaineer Shovel

- IDNO:

- 003297

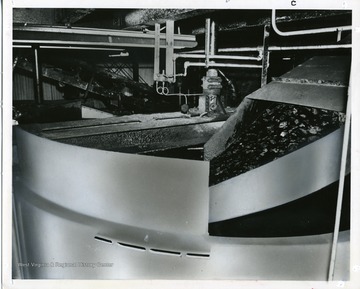

- Title:

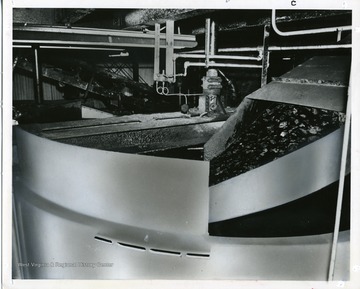

- Washing Coal with the Chance Cone System, Williams Preparation Plant, Pittsburgh Consolidation Coal Company

- Description:

- 5 x 3/8 inch raw coal flowing into the chance cone system.

- IDNO:

- 003304

- Title:

- Consolidation Coal Company Executives at a Golf Course

- IDNO:

- 003305

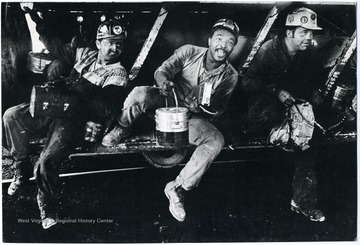

- Title:

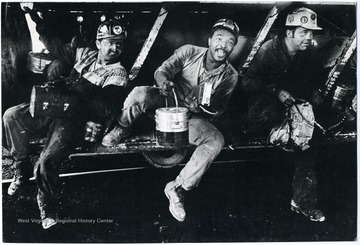

- Coal Miners Riding on a Shuttle

- Date:

- ca. 1976

- IDNO:

- 003310

- Title:

- Miners of Price Hill, W. Va.

- Description:

- Group portrait of miners at Price Hill, W. Va.

- IDNO:

- 003322

- Title:

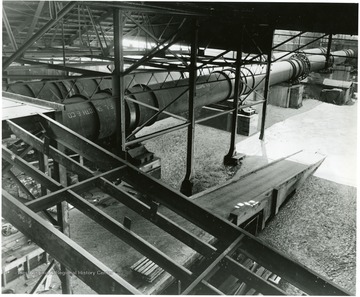

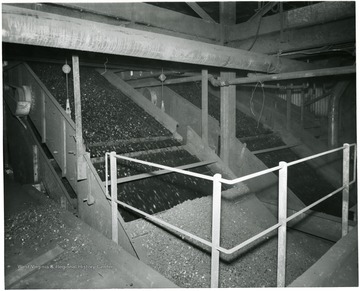

- Deister Cleaning Table

- Description:

- Possibly cleaning slack coal.

- IDNO:

- 003331

- Title:

- Loading Ramp to Cement Floor

- IDNO:

- 003332

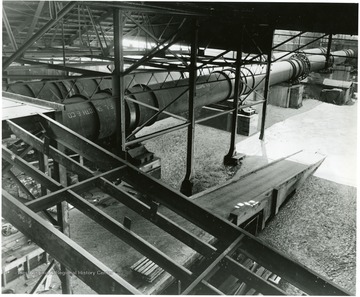

- Title:

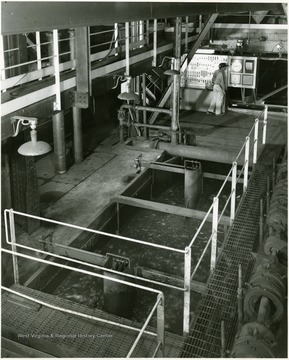

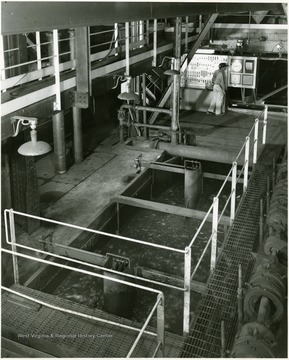

- Jeffrey Baum Jig at Jamison No. 9

- Date:

- 1954/10/05

- Description:

- Used to improve coal quality by reducing the ash.

- IDNO:

- 003345

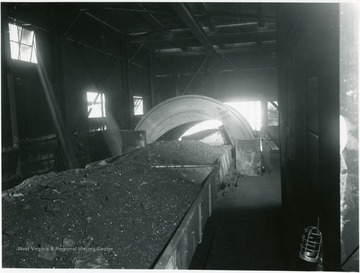

- Title:

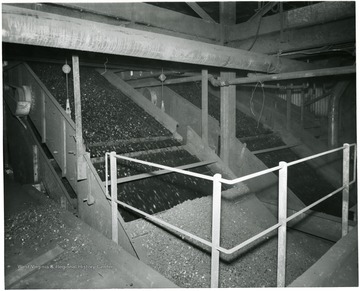

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003348

- Title:

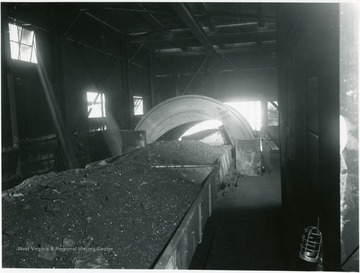

- Lump Coal Being Loaded onto Railroad Cars

- Description:

- 'All sizes of 'White Oak' prepared coal are loaded into railroad cars with loading booms to minimize breakage and preserve the best appearance of the coal. It would be useless to carefully mine and screen our coal if we did not use proper care in loading it into the railroad cars. These booms lower to the bottom of the car when it is first placed under the tipple for loading, and raised from time to time as the car fills up. Note how perfectly screened this lump coal appears on the boom! Not a sign of slack to be seen. Treated for dust if desired.'

- IDNO:

- 003355

- Title:

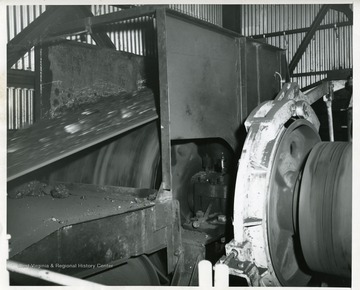

- Link-Belt Rotary Mine Car Dumper, Pocahontas Fuel Company, Itmann, W. Va.

- Date:

- 1951/11

- Description:

- 'Link-Belt 33460, Link-Belt rotary mine car dumper at Heavy-Media coal preparation plant of Pocahontas Fuel Co. Inc., Itmann, W. Va. Capacity of plant is 750 tons of raw coal per hour. Nov. 1951'