Search Results

- IDNO:

- 003325

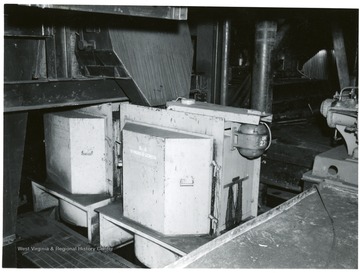

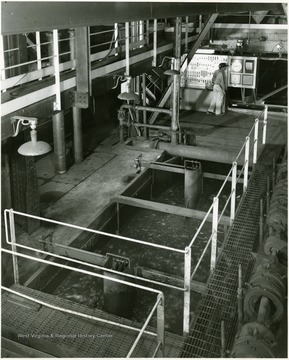

- Title:

- High Intensity Screens

- IDNO:

- 003326

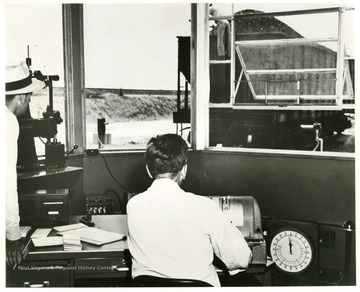

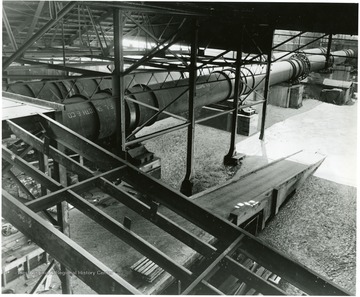

- Title:

- Head of Raw Coal Belt Conveyor with Magnetic Separator

- IDNO:

- 003327

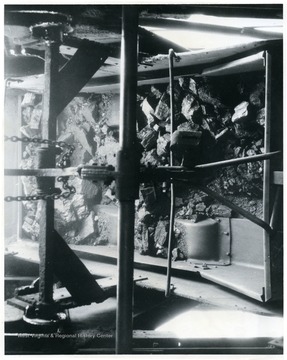

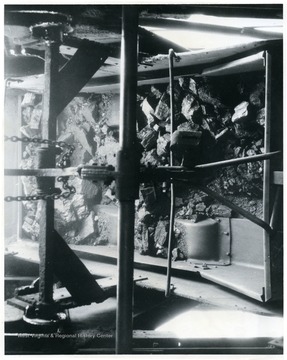

- Title:

- Coal in Self Dumping Cage

- Description:

- 'Coal at all White Oak shaft mines is handled on self dumping cages, which handle coal uniformly and with a minimum of breakage. Note how evenly the coal is flowing from the mine car. Much more rapid course than the picture indicates, but it shows how well designed the equipment must be to handle the coal in such a splendid manner.'

- IDNO:

- 003328

- Title:

- Coal on Conveyor

- Description:

- 'All sizes of 'White' prepared coal is loaded into railroad cars with loading booms to minimize breakage and preserve the best appearance of the coal. It would be useless to carefully mine and screen our coal if we did not use proper care in loading it into the railroad cars. These booms lower to the bottom of the car when it is first placed under the tipple for loading, and raised from time to time as the car fills up. Note how perfectly screened this lump coal appears on the boom! Not a sign of slack to be seen. Treated for dust if desired.'

- IDNO:

- 003329

- Title:

- Steel Mine Car

- Description:

- 'This is an end view of one of our new steel mine cars on a cage at one of the White Oak Shaft mines, and the signal has just been given to hoist it to the surface, 450 feet up! These electric equipped hoists can hoist a car every twenty seconds and dump it! The cars are placed on the cages and automatically by creeper chains and car stops. One man operates the signals and car stops and chains.'

- IDNO:

- 003330

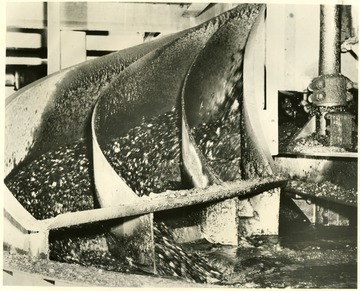

- Title:

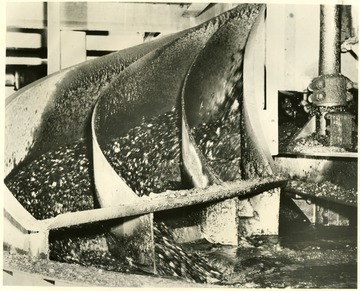

- Chance Cone Feeding Coal

- Description:

- 'The sheltered construction of the processing equipment makes it difficult to photograph the coal in flow through the circuits, but this is a flash of the raw coal feed pouring into the 16.5 foot Chance cone. In this cone-shaped vessel, a mixture of sand and water is kept at a controlled gravity by agitation and by control of the proportions. This gravity is set to separate the clean coal from the refuse. The lighter coal is floated on top of the mix and guided to a discharge to continue its processing, which includes desanding, scrubbing, sizing, and moisture removal. The heavier refuse meanwhile sinks to the bottom and is passed to the refuse disposal system. This large cone has a capacity of 500 tons per hour.'

- IDNO:

- 003331

- Title:

- Loading Ramp to Cement Floor

- IDNO:

- 003332

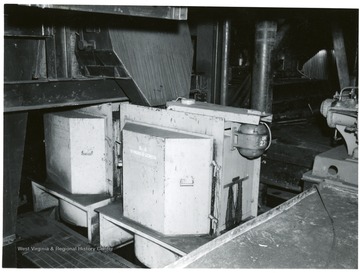

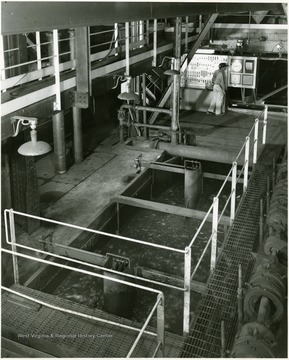

- Title:

- Jeffrey Baum Jig at Jamison No. 9

- Date:

- 1954/10/05

- Description:

- Used to improve coal quality by reducing the ash.

- IDNO:

- 003333

- Title:

- Flat Bed with Water, Pittsburgh Consolidation Coal Company

- IDNO:

- 003334

- Title:

- Washing Coal with the Chance Cone System, Williams Preparation Plant, Pittsburgh Consolidation Coal Company

- IDNO:

- 003335

- Title:

- Loading Coal at a Coal Preparation Plant

- IDNO:

- 003336

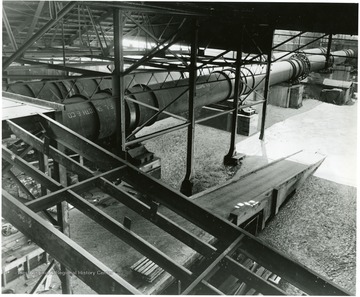

- Title:

- Heat Drier Building

- Description:

- 'On the top level of the heat drier building showing, from left to right, the motors, blowers and tops of the cyclones. The vertical tubes are exhaust stacks for the waste heating gases and moisture. The driers themselves are long, vertical tubes, located beneath this deck. A blast of hot gasses dries the coal and the cyclones then separate the coal from the waste gasses and moisture. Purpose of the drying operation is to reduce the moisture acquired in coal washing, 'or from the atmosphere during storage on the stock pile', and provide the processing plant with a uniform charge material.