Search Results

- IDNO:

- 003331

- Title:

- Loading Ramp to Cement Floor

- IDNO:

- 003335

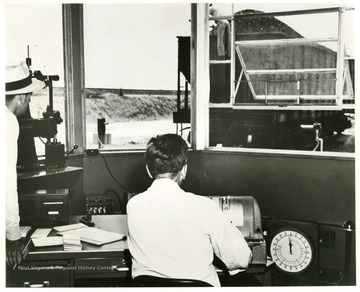

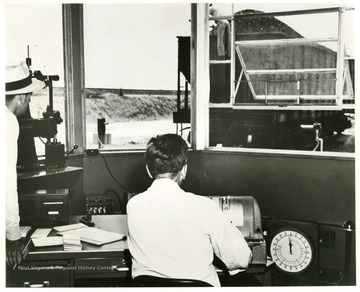

- Title:

- Loading Coal at a Coal Preparation Plant

- IDNO:

- 003336

- Title:

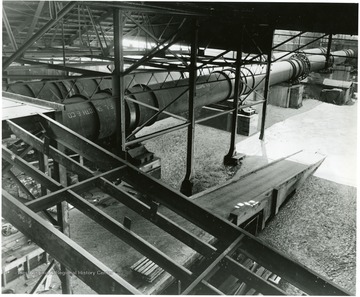

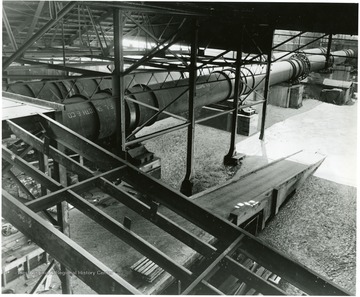

- Heat Drier Building

- Description:

- 'On the top level of the heat drier building showing, from left to right, the motors, blowers and tops of the cyclones. The vertical tubes are exhaust stacks for the waste heating gases and moisture. The driers themselves are long, vertical tubes, located beneath this deck. A blast of hot gasses dries the coal and the cyclones then separate the coal from the waste gasses and moisture. Purpose of the drying operation is to reduce the moisture acquired in coal washing, 'or from the atmosphere during storage on the stock pile', and provide the processing plant with a uniform charge material.

- IDNO:

- 003351

- Title:

- Conveyor Belt at Jamison No. 9

- Description:

- Coal traveling on a conveyor.

- IDNO:

- 003354

- Title:

- Interior of the Hutchinson Preparation Plant

- Description:

- Miner examines coal traveling down a conveyor inside the Hutchinson Preparation Plant, Pittsburgh Consolidation Coal Company.

- IDNO:

- 003363

- Title:

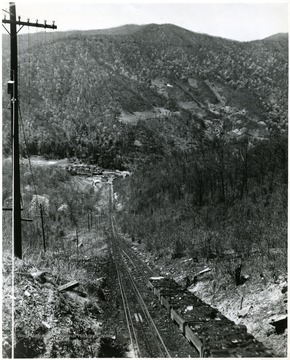

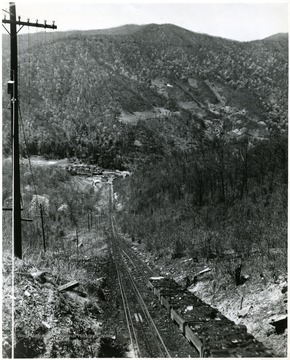

- Incline at Clover Splint Mine

- Date:

- 1952/05/02

- Description:

- The incline is 4360 feet long and has a vertical rise of 1335 feet. Six cars each carrying 4 tons each would be loaded each trip.

- IDNO:

- 003365

- Title:

- Coaling Station

- Description:

- A few mine buildings and some houses.

- IDNO:

- 003366

- Title:

- Raw Coal Conveyor System

- Description:

- Conveyor belt in the middle of the mountains.

- IDNO:

- 003369

- Title:

- Champion No. 1 Preparation Plant

- Description:

- Filled coal cars outside of the Preparation Plant.

- IDNO:

- 003372

- Title:

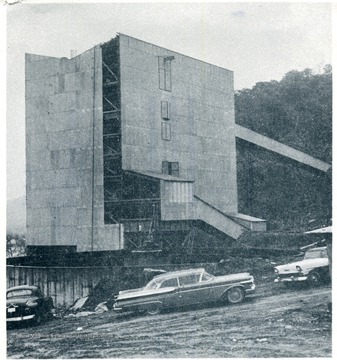

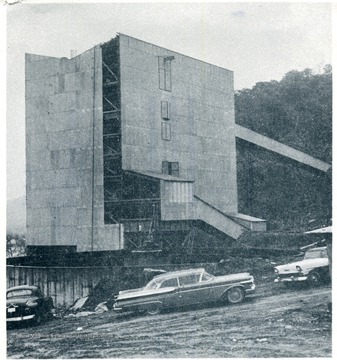

- Ireland Mine Preparation Plant

- Description:

- 'The Plus 6" coal will be crushed to minus 1.5" and two 16,6" Chance Cones will wash the 6 x 3/8 coal. Current production of approximately 1800 tons per day is crushed to minus 1.25" then trucked to the storage yard of the new Kammer Power plant.'

- IDNO:

- 003375

- Title:

- Ireland Mine Portal Area Supply Slope

- Date:

- 1958/06/01

- IDNO:

- 003376

- Title:

- Mathies Mine Preparation Plant

- Description:

- Coal buildings at the Mathies Mine, a division of Pittsburgh Consolidation Coal Co.