Search Results

- IDNO:

- 003339

- Title:

- Coal Conveyors in Action at Arkwright

- IDNO:

- 003340

- Title:

- Coal Being Processed at Champion Cleaning Plant

- Date:

- 1929/02/18

- IDNO:

- 003341

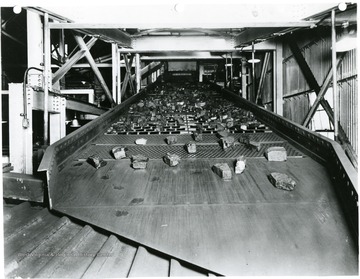

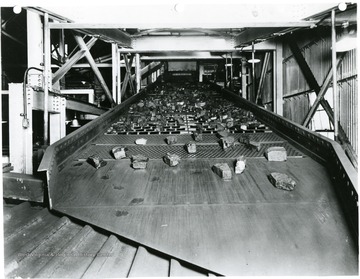

- Title:

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'

- IDNO:

- 003342

- Title:

- Coal Cars at Lochgelly Mine

- Date:

- 1952/04/20

- IDNO:

- 003343

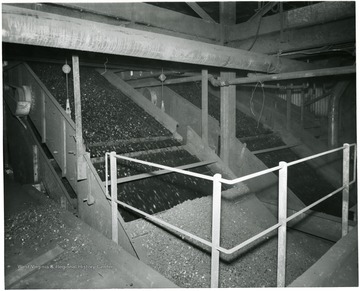

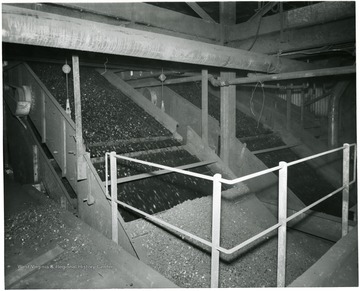

- Title:

- Main Shaker Screen and Step Plate

- Description:

- Coal moves across the main shaker screen.

- IDNO:

- 003344

- Title:

- Double Deck Vibrating Screens, Making Two Sizes of Stoker Coal

- IDNO:

- 003345

- Title:

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003346

- Title:

- Stoker Coal at Williams Preparation Plant

- Description:

- Coal traveling down a conveyor for processing.

- IDNO:

- 003347

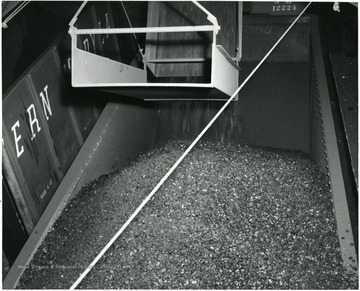

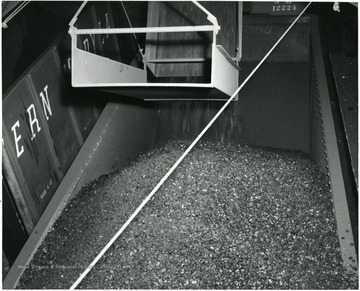

- Title:

- Coal Loading in Process

- Description:

- Coal filling a bin.

- IDNO:

- 003348

- Title:

- Lump Coal Being Loaded onto Railroad Cars

- Description:

- 'All sizes of 'White Oak' prepared coal are loaded into railroad cars with loading booms to minimize breakage and preserve the best appearance of the coal. It would be useless to carefully mine and screen our coal if we did not use proper care in loading it into the railroad cars. These booms lower to the bottom of the car when it is first placed under the tipple for loading, and raised from time to time as the car fills up. Note how perfectly screened this lump coal appears on the boom! Not a sign of slack to be seen. Treated for dust if desired.'

- IDNO:

- 003349

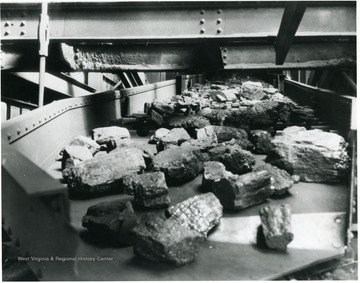

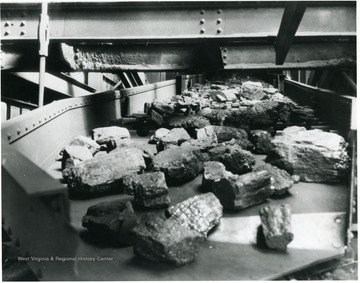

- Title:

- Screening and Sizing

- Description:

- 'The size and design of the shaker screens now in use at the White Oak mines are the best that an experience of twenty years in preparing Smokeless Coal has found to be the best and yield a satisfactory screened and sized coal. A screen must first be of ample size to take care of the amount of tonnage passing over it, because crowding and overloading a screen results in poorly screened and poorly sized coal. The screen shown in this picture is handling 400 tons per hour and still has ample screening space to spare. The flow of coal over these big 'White Oak' shaker screens is controlled by a feeder which cannot be tampered with; therefore, the screen cannot be overloaded. Note the 'lip' type of slotted screen plate used. It cannot become stopped up by coal sticking in the slots because the slots are wider at the base than at the top and are there fore self clearing. The 'lips' keep the coal turning over and over so it is impossible for slack to ride over on the larger pieces. The coal never falls; it is always sliding while being screened which helps prevent breakage. Note the uniform size and firm character of the lump coal which has passed over the egg screen shown in this picture.'

- IDNO:

- 003350

- Title:

- Loading Booms in Action

- Date:

- undated

- Description:

- 'Shown here are the loading booms in action. Each of the five loading tracks is served by a loading boom, and the loading system is interconnected so as to permit blending of sizes and loading of any size group on any track. The loading booms gently lower the coal into the cars with a minimum of opportunity for dust or degradation. The loading facilities are sufficient to permit the loading of a car every two minutes. The adjoining track system permits rapid assembly of trains, interchange between the two railraods, and sufficient trackage for the storage of 858 railroad cars of 70 ton capacity.'