Search Results

- IDNO:

- 003375

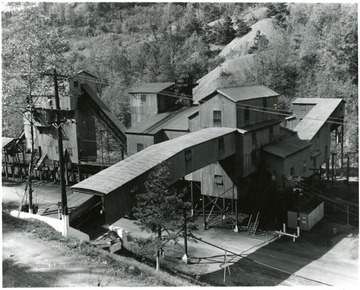

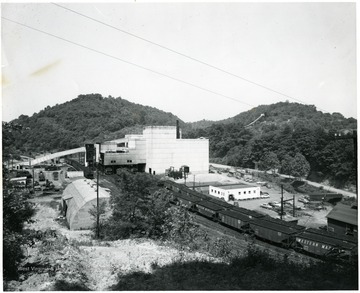

- Title:

- Ireland Mine Portal Area Supply Slope

- Date:

- 1958/06/01

- IDNO:

- 003376

- Title:

- Mathies Mine Preparation Plant

- Description:

- Coal buildings at the Mathies Mine, a division of Pittsburgh Consolidation Coal Co.

- IDNO:

- 003377

- Title:

- Mine No. 155 Tipple, Consolidation Coal Company, Van Lear, Kentucky

- Date:

- 1947/10/20

- IDNO:

- 003378

- Title:

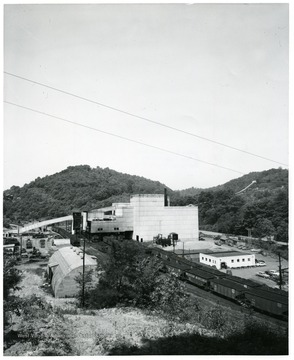

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Filled coal cars are lined up outside of the Williams Preparation Plant.

- IDNO:

- 003379

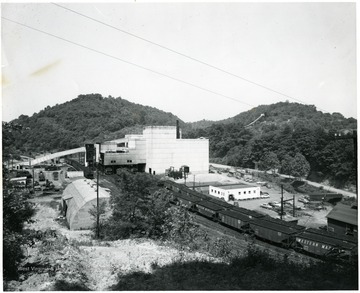

- Title:

- Georgetown Preparation Plant

- Description:

- 'The Georgetown Preparation Plant is the world's largest commercial coal preparation plant, having a capacity of 1,500 tons per hour of raw coal, or 1,275 tons per hour of clean coal. The plant has facilities for dumping bottom-dump tractor-trailer and end-dump trucks, and for rotary and bottom dumping of railroad cars. Coal from these dumps goes into a 1,500 ton bin, from which it is conveyed on a 641 foot belt conveyor to the primary shaker screens. Whereas the conventional coal perparation plant provides only one circuit for all coal washed, the Georgetown plant is unique, in that it provides three separate washing circuites, each of which is designed to most efficiently clean a certain size fraction.'

- IDNO:

- 003380

- Title:

- Georgetown Preparation Plant

- Description:

- Division of the Pittsburgh Consolidation Coal Co.

- IDNO:

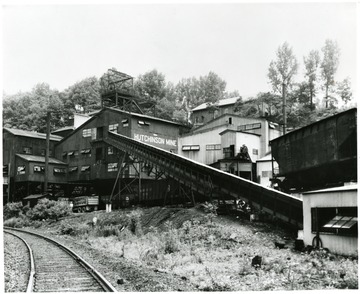

- 003381

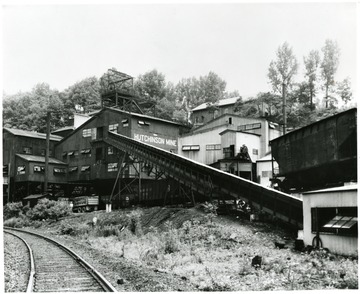

- Title:

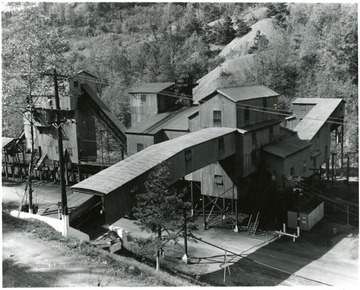

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/12

- Description:

- Mine cars and buildings around the preparation plant.

- IDNO:

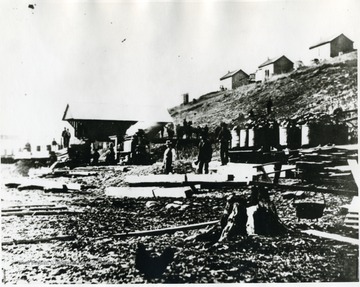

- 003382

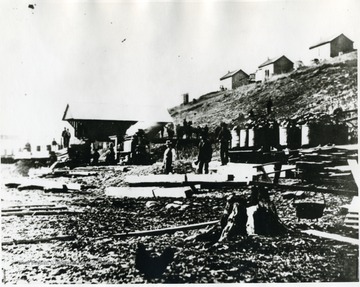

- Title:

- Gaston Mine Plant, Gaston Gas Coal Company

- Description:

- Mine was 1/2 mile south of Hunsaker bridge on West Fork River. Owned by James Otis Watson, the mine was founded in 1875 and closed in 1925.

- IDNO:

- 003383

- Title:

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/10

- Description:

- Mine cars and buildings around the preparation plant.

- IDNO:

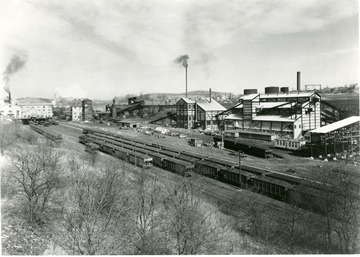

- 003384

- Title:

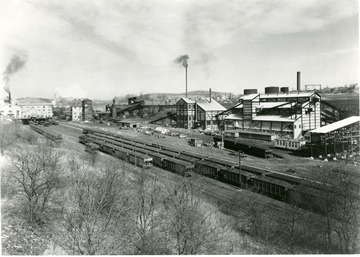

- Disco Plant with Champion No. 1 Preparation Plant in Background

- Description:

- Line of large coal buildings. Filled coal cars lined up outside as well.

- IDNO:

- 003385

- Title:

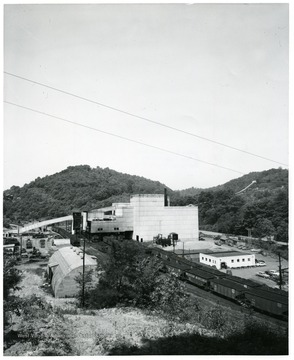

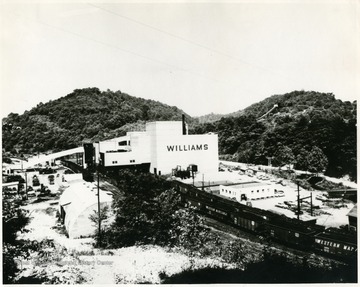

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Large preparation plant with filled coal cars lining the outside.

- IDNO:

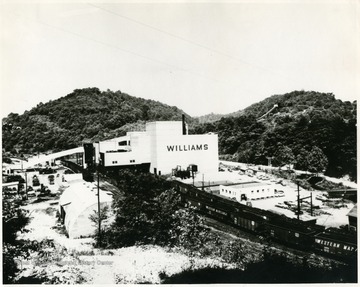

- 003386

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Date:

- ca. 1953

- Description:

- 'An overall view of the new plant at Williams No. 98 Mine of Consolidation Coal Compnay (W. Va.) is shown. Coal comes from the mine on a 558 foot conveyor belt at the left to the top of the plant past the old tipple (shown dark against the new structure) which is now being removed. Through intricate processes it is screened and sized and loaded into railroad cars on four tracks which pass under the tipple (center). Impurities removed from the coal are carried on another long conveyor to a hilltop slate dump shown in the extreme upper right corner. This mine is named for Eugene Williams of Romney, W. Va. Mr. Williams is Chairman of the Board of Western Maryland Railroad. Williams Preparation Plant, convering over three acres of floor space on eight levels is a steel and concrete structure 100 feet high and fully enclosed without a single window. this windowless 'factory' is a mystifying innovation to all who visit the plant. It is equipped with a ventilating system, fluorescent lighting, and a complete vacuum type dust collection system that gather in all air borne particles at their source. All of these measures promote health, safety and good housekeeping. The raw coal is delivered to the preparation plant at a rate of 450 tons per hour by a 558 foot belt which picks up the coal at the rotary mine car dump at the bottom of the slope. After the coal is crushed down to 5 inch top size the raw coal is fed into a 15 foot diameter chance cone yielding 278 tons of 'float-kleen' coal per hour. The washing process operates on the principle of gravity separation, a fluid mass of sand and water being utilized as the density medium. Designed and built by Fairmont Machinery Company placed in operation March 31, 1953; No windows, dust collection system; track storage, 100 empties, 80 loads; Present daily capacity, 8500 tons; potential daily capacity, 15,000 tons; coal reserves, 80,000,000 tones, Pittsburgh seam; slack dried, centrifugal and thermal dryers; oil treating facilities for stoker grades; served by two railroads, WM and B&O; Plant named for Eugene Williams of Romney, W. Va. Board Chairman of the Western Maryland Railroad.'