Search Results

- IDNO:

- 003332

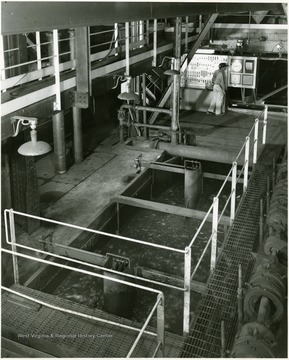

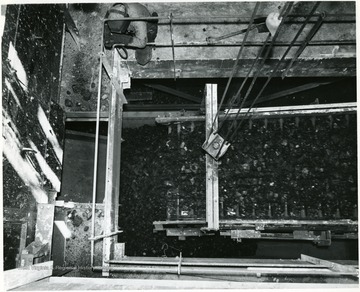

- Title:

- Jeffrey Baum Jig at Jamison No. 9

- Date:

- 1954/10/05

- Description:

- Used to improve coal quality by reducing the ash.

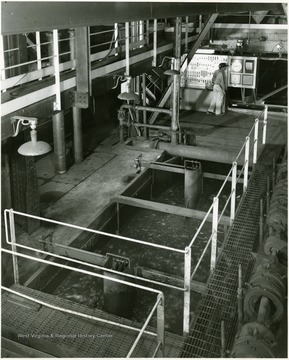

- IDNO:

- 003333

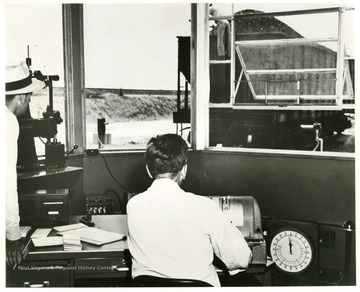

- Title:

- Flat Bed with Water, Pittsburgh Consolidation Coal Company

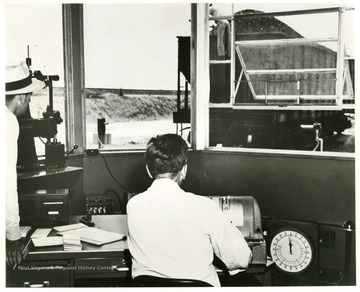

- IDNO:

- 003334

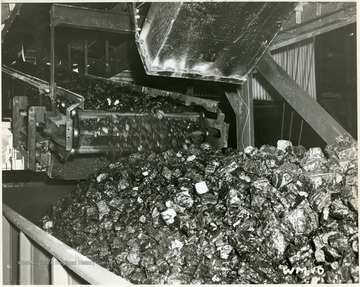

- Title:

- Washing Coal with the Chance Cone System, Williams Preparation Plant, Pittsburgh Consolidation Coal Company

- IDNO:

- 003335

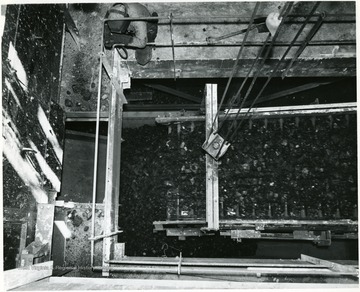

- Title:

- Loading Coal at a Coal Preparation Plant

- IDNO:

- 003336

- Title:

- Heat Drier Building

- Description:

- 'On the top level of the heat drier building showing, from left to right, the motors, blowers and tops of the cyclones. The vertical tubes are exhaust stacks for the waste heating gases and moisture. The driers themselves are long, vertical tubes, located beneath this deck. A blast of hot gasses dries the coal and the cyclones then separate the coal from the waste gasses and moisture. Purpose of the drying operation is to reduce the moisture acquired in coal washing, 'or from the atmosphere during storage on the stock pile', and provide the processing plant with a uniform charge material.

- IDNO:

- 003337

- Title:

- Loading Minus 5 Inch Coal at Williams Preparation Plant

- IDNO:

- 003338

- Title:

- Welder at Work Above a Loading Boom in a Preparation Plant

- IDNO:

- 003339

- Title:

- Coal Conveyors in Action at Arkwright

- IDNO:

- 003340

- Title:

- Coal Being Processed at Champion Cleaning Plant

- Date:

- 1929/02/18

- IDNO:

- 003341

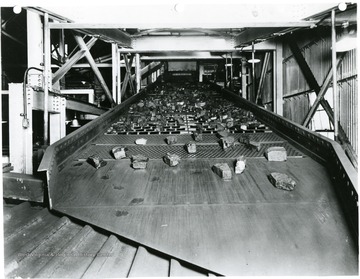

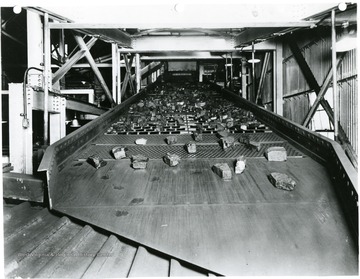

- Title:

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'

- IDNO:

- 003342

- Title:

- Coal Cars at Lochgelly Mine

- Date:

- 1952/04/20

- IDNO:

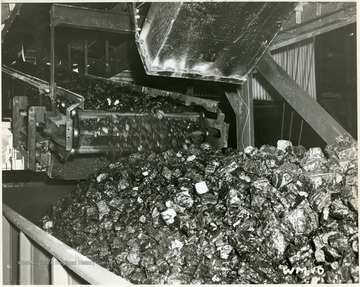

- 003343

- Title:

- Main Shaker Screen and Step Plate

- Description:

- Coal moves across the main shaker screen.