Search Results

- IDNO:

- 003368

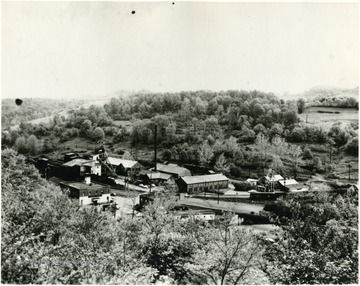

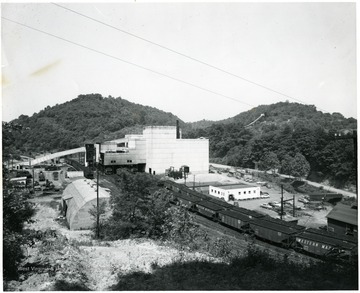

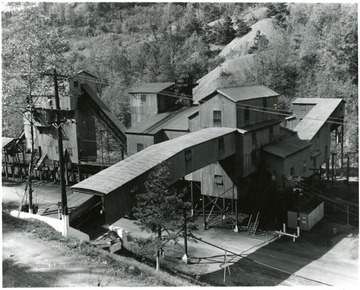

- Title:

- Federal Mine No. 1, Grant Town, W. Va.

- Description:

- Federal Mine No. 1 mine plant at Grant Town, W. Va.

- IDNO:

- 003369

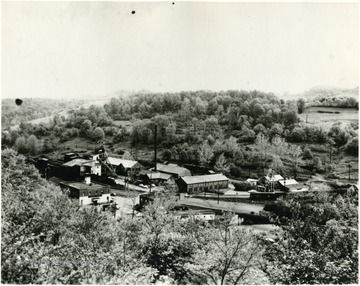

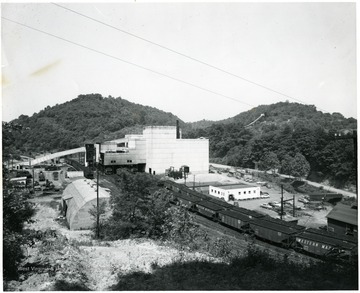

- Title:

- Champion No. 1 Preparation Plant

- Description:

- Filled coal cars outside of the Preparation Plant.

- IDNO:

- 003370

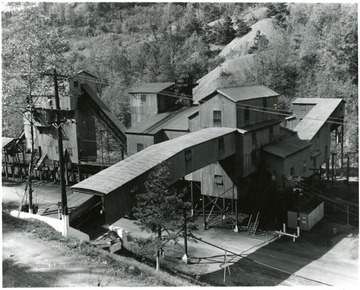

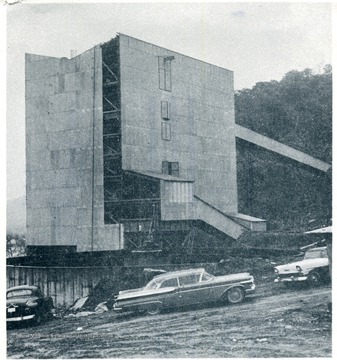

- Title:

- Mine No. 32, Owings, W. Va.

- Description:

- Side view of the preparation plant located on the B&O RR, Owings, W. Va.

- IDNO:

- 003371

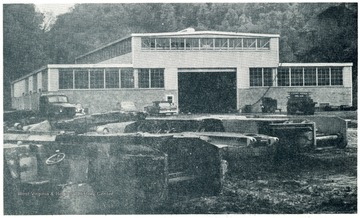

- Title:

- Ireland Mine Shamrock Portal Shop and Supply Slope

- Date:

- 1958/06/10

- Description:

- Cars and machinery are parked outside mine plant buildings.

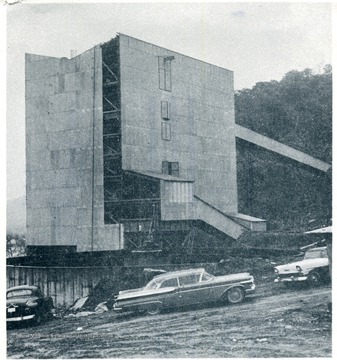

- IDNO:

- 003372

- Title:

- Ireland Mine Preparation Plant

- Description:

- 'The Plus 6" coal will be crushed to minus 1.5" and two 16,6" Chance Cones will wash the 6 x 3/8 coal. Current production of approximately 1800 tons per day is crushed to minus 1.25" then trucked to the storage yard of the new Kammer Power plant.'

- IDNO:

- 003373

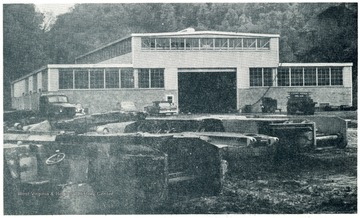

- Title:

- Ireland Mine Machine Shop Fully Equipped

- Description:

- 'Two Joy 3-JCM and one Goodman 300 continuous miners are now in service producing coal. These machines have roof bolting machines as an integral part of their equipment. Two Joy 3-JCM machines are also being used brushing top and bottom where additional height is needed in the main haulage entries.'

- IDNO:

- 003374

- Title:

- Mine No. 155 Preparation Plant, Consolidation Coal Company, Van Lear, Kentucky

- IDNO:

- 003375

- Title:

- Ireland Mine Portal Area Supply Slope

- Date:

- 1958/06/01

- IDNO:

- 003376

- Title:

- Mathies Mine Preparation Plant

- Description:

- Coal buildings at the Mathies Mine, a division of Pittsburgh Consolidation Coal Co.

- IDNO:

- 003377

- Title:

- Mine No. 155 Tipple, Consolidation Coal Company, Van Lear, Kentucky

- Date:

- 1947/10/20

- IDNO:

- 003378

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Filled coal cars are lined up outside of the Williams Preparation Plant.

- IDNO:

- 003379

- Title:

- Georgetown Preparation Plant

- Description:

- 'The Georgetown Preparation Plant is the world's largest commercial coal preparation plant, having a capacity of 1,500 tons per hour of raw coal, or 1,275 tons per hour of clean coal. The plant has facilities for dumping bottom-dump tractor-trailer and end-dump trucks, and for rotary and bottom dumping of railroad cars. Coal from these dumps goes into a 1,500 ton bin, from which it is conveyed on a 641 foot belt conveyor to the primary shaker screens. Whereas the conventional coal perparation plant provides only one circuit for all coal washed, the Georgetown plant is unique, in that it provides three separate washing circuites, each of which is designed to most efficiently clean a certain size fraction.'